Collection: Fuel Systems - Fuel Pumps, Regulators & AN Fittings

📋 Fuel System Plumbing Guide

→ Download our complete fuel system plumbing guide

Before you build your fuel system, download our comprehensive guide featuring:

- ✅ Fuel line sizing chart - Correct AN sizes by power output (carb and EFI)

- ✅ EFI vs carbureted systems - Different requirements explained

- ✅ Component selection - Pumps, regulators, filters, and braided hose

- ✅ Step-by-step installation - Professional plumbing techniques

- ✅ Safety guidelines - Critical fuel system safety procedures

- ✅ Pressure specifications - Correct fuel pressure for your application

- ✅ Troubleshooting guide - Fix fuel starvation, leaks, and vapor lock

- ✅ E85, methanol, and diesel - Special fuel type considerations

→ View the full fuel system plumbing guide here

Complete Fuel System Components - Pumps, Regulators & AN Plumbing

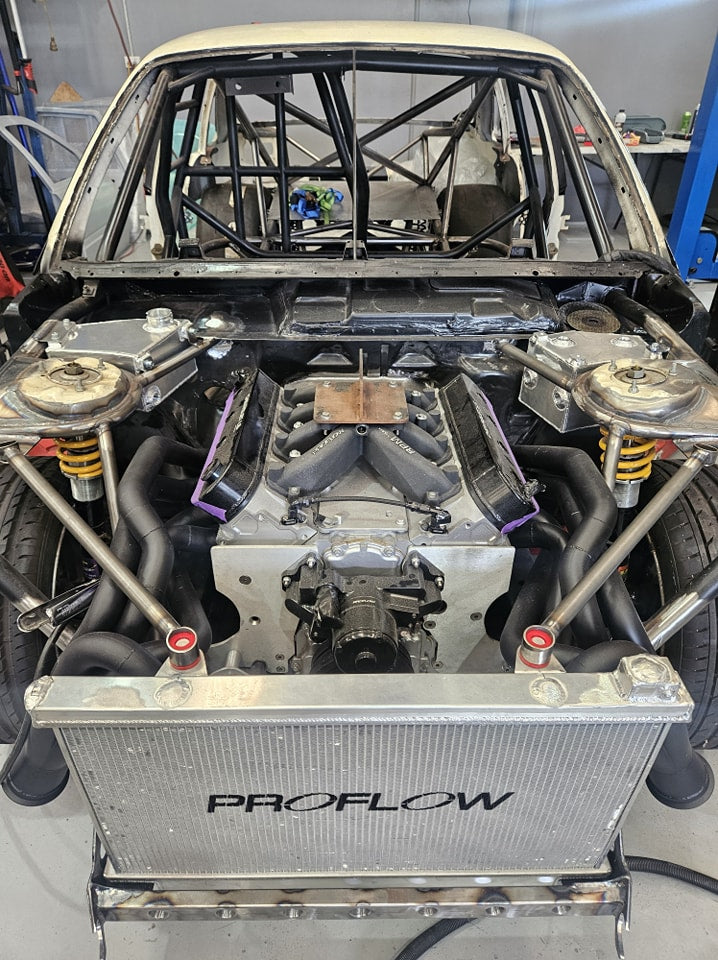

Build a reliable, high-performance fuel system with professional-grade components designed for Australian street machines, race cars, and custom builds. From electric fuel pumps and pressure regulators to braided stainless hose and AN fittings, we stock everything you need for carbureted, EFI, and race fuel systems.

Fuel Delivery Components

- Fuel Pumps: Electric in-tank and inline pumps (40-500+ LPH) plus mechanical pumps for carbureted and EFI applications

- Fuel Pressure Regulators: Adjustable regulators for carb (4-9 PSI) and EFI (30-70 PSI) systems with return and returnless configurations

- Fuel Filters: Inline filters with 10-100 micron elements to protect injectors and carburetors from contamination

- Fuel Pressure Gauges: Liquid-filled gauges and digital displays for accurate fuel pressure monitoring

- Fuel Rails: Billet aluminium fuel rails for LS, Holden, and Ford EFI conversions

AN Fuel Line & Fittings

- Speedflow Braided Hose: PTFE-lined braided stainless steel hose in -4AN to -12AN sizes for fuel, oil, and coolant

- Speedflow AN Fittings: Complete range of hose ends, adapters, bulkhead fittings, and specialty fittings

- AN Hose Ends: 100, 200, and 400 series reusable hose ends in straight, 30°, 45°, 60°, 90°, 120°, 150°, and 180° configurations

- AN Adapters: Male-to-male, female-to-female, reducer, and specialty adapters for custom plumbing

- Bulkhead Fittings: Pass-through fittings for fuel lines through firewalls and panels

Fuel Tank Components

- Weld Bungs: Male AN and female ORB weld bungs for custom fuel tank fabrication and plumbing

- Fuel Tank Senders: Capacitive and resistive fuel level senders for custom tanks

- Fuel Caps & Bungs: Vented and non-vented fuel caps with AN fittings

- Fuel Cell Fittings: Bulkhead fittings, rollover valves, and vent fittings for racing fuel cells

Complete your fuel system with complementary components:

- Holley Small Parts: Jets, gaskets, and rebuild components for Holley carburetors

- Intake Manifolds: Proflow manifolds for LS, Holden, and Ford applications

- Oil Systems: Oil pans, pumps, and AN plumbing components

- Fabrication Parts: Weld bungs, fittings, and custom fabrication supplies

Fuel System Installation Resources

- 100 Series Hose Ends Installation Guide

- 200 Series Hose Ends Installation Guide

- 400 Series Hose Ends Installation Guide

- Weld Bung Installation Guide

Australian Stock

All fuel system components are in stock and ready to ship from Perth, Western Australia.

Fast Shipping Across Australia - Same-day dispatch on orders placed before 2 PM AWST.

-

Proflow Fuel Pressure Gauge 0-100 PSI - 40mm Black Body Black Face 1/8 NPT PFEFG-100BK-2

Vendor:SS Racetech Rods & CustomsRegular price $53.95 AUDRegular price -

Proflow Fuel Pressure Gauge 0-15 PSI Black - 40mm Liquid Filled | PFEFG-015BK-2

Vendor:SS Racetech Rods & CustomsRegular price $53.95 AUDRegular price -

Proflow Fuel Pressure Regulator Carb Bypass 4-13 PSI - 4 Port Billet Aluminium Universal PFEFS13204

Vendor:SS Racetech Rods & CustomsRegular price $223.45 AUDRegular price -

Proflow Fuel Pressure Regulator EFI Pro 3-Port 30-65 PSI - Billet Aluminium -08AN Universal PFEFS13128

Vendor:SS Racetech Rods & CustomsRegular price $232.60 AUDRegular price -

Proflow Fuel Pressure Regulator Carb 2-Port 3-10 PSI - Billet Aluminium Series II -06AN Universal PFEFS13220

Vendor:SS Racetech Rods & CustomsRegular price $216.30 AUDRegular price -

Proflow Electric Fuel Pump Rotary Vane 100 GPH 15 PSI 3/8" NPT Black - PFEFS14000

Vendor:SS Racetech Rods & CustomsRegular price $160.95 AUDRegular price -

Proflow Electric Fuel Pump Rotary Vane 100 GPH 7 PSI 3/8" NPT Black/Silver - PFEFS14040

Vendor:SS Racetech Rods & CustomsRegular price $179.30 AUDRegular price -

Proflow Electric Fuel Pump Rotor Vane 110 GPH @ 14 PSI - 3/8 NPT Cast Aluminium Blue with Regulator Kit PFEFS12802-1

Vendor:SS Racetech Rods & CustomsRegular price $160.95 AUDRegular price -

Proflow Electric Fuel Pump Rotor Vane 97 GPH @ 7 PSI - 3/8 NPT Cast Aluminium Red PFEFS12801

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $150.50 AUDRegular price -

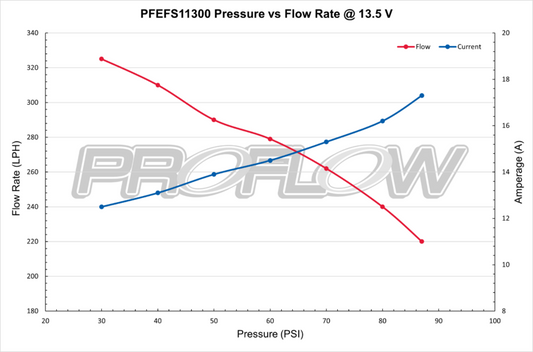

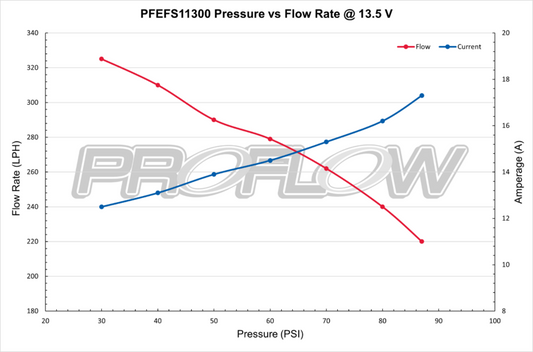

Proflow Fuel Pump Bosch Style 044 300 LPH @ 45 PSI - 650 HP In-Tank External Universal PFEFS11300

Vendor:SS Racetech Rods & CustomsRegular price $159.60 AUDRegular price -

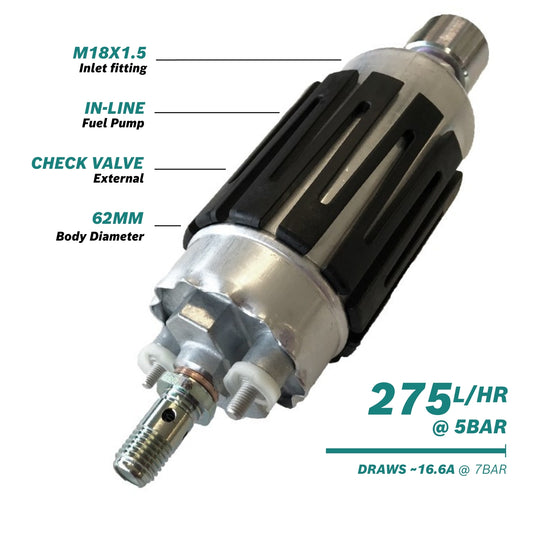

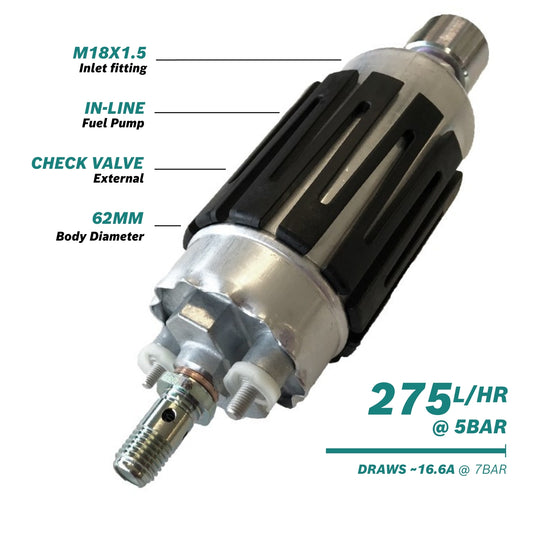

Bosch Fuel Pump, 044 Electric, 275 I/h @ 5Bar , External, Inline, Gasoline, Universal, Inlet 14mm x 1.5, Outlet 10mm x1.0 Each BOS0580464200

Vendor:SS Racetech Rods & CustomsRegular price $366.00 AUDRegular price -

Currently Unavailable

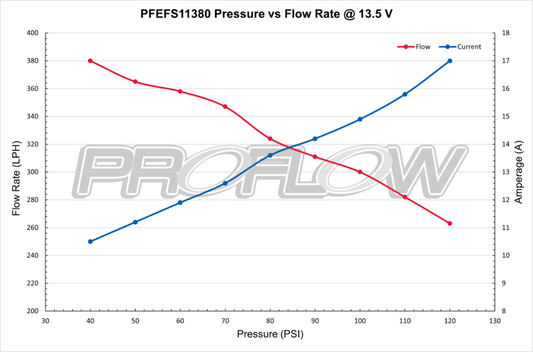

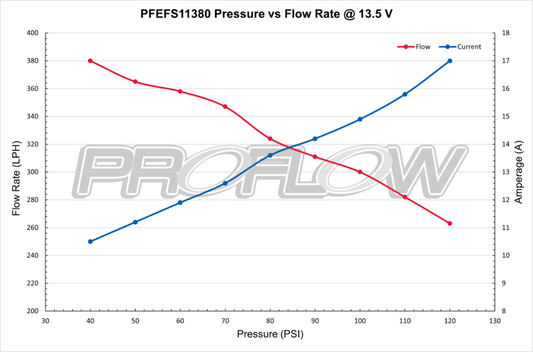

Currently UnavailableProflow Bosch Style 044 Fuel Pump Electric 380 LPH 5 Bar 1000HP External (PFEFS11380)

Vendor:SS Racetech Rods & CustomsRegular price $208.30 AUDRegular price -

Proflow In-Tank Fuel Pump 340 LPH @ 40 PSI - 600 HP E85 Compatible Electric PFEFS11150

Vendor:SS Racetech Rods & CustomsRegular price $190.30 AUDRegular price -

Proflow In-Tank Fuel Pump Kit 460 LPH 30 PSI 750 HP Walbro Style E85 Compatible - PFEFS11480

Vendor:SS Racetech Rods & CustomsRegular price $202.75 AUDRegular price -

Proflow P1200 EFI Fuel Pump 600 LPH 1200 HP - Billet Aluminium In-Line -12AN E85 Compatible PFEFS11001

Vendor:SS Racetech Rods & CustomsRegular price $599.00 AUDRegular price -

Currently Unavailable

Currently UnavailableCAR-P4594 Carter Universal Rotary Vane Electric Fuel Pump 72GPH 7PSI

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $170.30 AUDRegular price -

2.5L Fuel Surge Tank - Fabricated Aluminium Square Slim | 044 Pump Mounts | Black Powder Coat | PFEST7BK

Vendor:SS Racetech Rods & CustomsRegular price $351.25 AUDRegular price -

5L Fuel Surge Tank - Fabricated Aluminium Square | 044 Pump Mounts | Black Powder Coat | PFEST6BK

Vendor:SS Racetech Rods & CustomsRegular price $355.85 AUDRegular price -

Currently Unavailable

Currently Unavailable601-010-06-BLK -610u filter short series

Vendor:SS Racetech Rods & CustomsRegular price $253.10 AUDRegular price -

Currently Unavailable

Currently Unavailable601-010-08-BLK -08 filter short series

Vendor:SS Racetech Rods & CustomsRegular price $253.10 AUDRegular price -

602-010-06-BLK -06 10U filter long series

Vendor:SS Racetech Rods & CustomsRegular price $263.60 AUDRegular price -

602-010-08-BLK -8 10U filter long series

Vendor:SS Racetech Rods & CustomsRegular price $263.60 AUDRegular price -

602-010-10-BLK -10 10u filter long series

Vendor:SS Racetech Rods & CustomsRegular price $263.60 AUDRegular price -

602-065-06-BLK -6 65U filter long series

Vendor:SS Racetech Rods & CustomsRegular price $263.60 AUDRegular price

Shop by Engine

View all-

Air Filters - High-Flow Performance & Reusable Filters

High-Performance Air Filters - Washable, Reusable & High-Flow Maximize engine performance and...

-

Alternators & Accessories - High-Output Alternators & Brackets

Alternators & Accessories - High-Output Alternators & Mounting Brackets Upgrade your vehicle's...

-

Speedflow Hose - Braided Stainless Hose for Fuel, Oil & Brake

Premium Speedflow Braided Hose - Fuel, Oil, Coolant & Brake Lines Complete...

-

Speedflow Fittings

Premium Speedflow AN Fittings, Hose Ends & Adapters for High-Performance Plumbing Complete...

-

Engine Accessories - Performance Parts & Upgrades

Premium Engine Accessories - Performance Parts for Custom Builds & Motorsport Upgrade...

-

Fabrication Parts - Exhaust, Mandrel Bends & Weld Fittings

Premium Fabrication Parts - Custom Exhaust, Intake & Chassis Components Complete your...

-

ARP Fasteners - Head Studs, Main Studs & Rod Bolts

ARP Fasteners - Premium Head Studs, Main Studs & Engine Bolts Build...

-

Fuel Systems - Fuel Pumps, Regulators & AN Fittings

📋 Fuel System Plumbing Guide → Download our complete fuel system plumbing...

-

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps Upgrade...

-

Stainless Steel & Aluminium Bends and Tube

Premium Mandrel Bends & Tube for Custom Exhaust Fabrication Professional-grade stainless steel...

-

Racing Seats

Shop Proforce Safety racing seats at SS Racetech Rods & Customs. Experience...

-

Safety Equipment - Quick Release Latches & Bonnet Pins

Safety Equipment - Quick Release Latches, Bonnet Pins & Racing Safety Ensure...

-

Suspension - Uniball Bearings, Rod Ends & Bushings

Premium Suspension Components - Uniball Bearings, Rod Ends & Bushings Upgrade your...

-

Rod Ends & Uniballs - FK Heim Joints

Premium Rod Ends, Uniballs & Heim Joints for Steering & Suspension High-performance...

-

Carburetors & Accessories - Spacers, Studs & Fuel Line Kits

Carburetors & Accessories - Spacers, Mounting Hardware & Fuel Lines Optimize your...

-

Gaskets - Intake, Exhaust & Engine Gasket Sets

Engine Gaskets - Intake, Exhaust & Complete Gasket Sets High-quality gaskets for...

-

Forced Induction

Forced Induction - Turbocharger Parts & AccessoriesPremium forced induction components for turbocharged...

-

Proflow Intake Manifolds - LS Holden Ford

High-Performance Proflow Intake Manifolds for LS, Holden & Ford EnginesUnlock peak engine...

-

Fuel Injection, Throttle Body's & Fuel Rails

Fuel Injection, Throttle Bodies & Fuel Rails – Precise Fuel Delivery for...

-

Cooling Systems - Oil Coolers, Transmission Coolers & Water Pumps

High-Performance Cooling Systems - Oil Coolers, Transmission Coolers & Heat Management Keep...

-

Drivetrain Components - Transmission & Driveline Parts

High-Performance Drivetrain, Transmission & Driveline ComponentsPremium drivetrain parts for reliable power transfer...

-

Race Suits / Apparel - Order in available!

Order in available! (We want to supply you with the newest dates...

-

Shocks & Springs

Fox bypass kit, Shaft, Bottom eyelet, King shocks rebuild kit, Fox mounting...

-

Silicone Hose, Bends and Reducers

Premium Silicone Hoses, Bends, Reducers & Brake Duct Hose SS Racetech stocks...

-

Steering & Shifters - Steering Columns & U-Joints

Steering & Shifters - Precision Control Components for Custom Builds Upgrade your...

-

Bearings & Seals

This collection offers Timken bearings, set 38, and oil seals. Find tapered...

-

Lubricants & Chemicals

Shop top-quality multi-purpose lubricant for cars and other high-performance automotive chemicals. Keep...

-

Electrical Components - Ignition, Alternators & Wiring

High-Performance Electrical Components - Ignition Systems, Alternators & Wiring Upgrade your vehicle's...

-

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds...

-

Custom Engines - Engine Rebuilds & Performance Builds

Custom Engine Builds - Rebuilds, Performance Upgrades & Complete Engines Unlock your...

-

Metric & Imperial Fasteners

SS Racetech Rods & Customs is your trusted source for...

-

Tyres & Wheels

Performance Tyres & Wheels for Race Cars & Street Machines High-performance tyres...

-

Drives & Pulleys - Performance Pulleys & Belt Tensioners

Drives & Pulleys - Performance Pulleys & Belt Tensioners Optimize your engine's...