Collection: Oil Systems - Oil Pans, Pumps, Coolers & Breathers

Premium Oil System Components - Oil Pans, Pumps, Coolers & Breathers

Build a reliable, high-performance oil system with our comprehensive range of components designed for Australian street machines, race cars, and custom builds. From baffled oil pans and high-volume pumps to oil coolers, catch cans, and AN plumbing, we stock everything you need for proper lubrication, cooling, and pressure management in demanding applications.

Oil System Accessories

- Engine Dipsticks: Billet aluminium dipsticks with accurate calibration for custom oil pans

- Oil Pressure Gauges: Mechanical and electronic gauges for accurate oil pressure monitoring

- Oil Temperature Gauges: Monitor oil temperature to prevent overheating and breakdown

- AN Fittings & Adapters: Complete range of hose ends and adapters for custom oil system plumbing

- Weld Bungs: AN and ORB weld fittings for custom oil pan and block installations

Why Upgrade Your Oil System?

Factory oil systems are designed for stock power levels and normal driving conditions. Modified engines with increased horsepower, high-RPM operation, or track use generate more heat and require better oil control than stock components can provide. Oil starvation causes bearing failure, rod knock, and catastrophic engine damage. Upgrading to a performance oil system with baffled pan, high-volume pump, and oil cooler maintains consistent oil pressure, reduces oil temperatures, and protects your investment in demanding conditions.

Related Engine Components

Complete your oil system upgrade with complementary components:

- Cooling Systems: Oil coolers, transmission coolers, and cooling components

- Engine Accessories: Water pumps, valve covers, and performance engine components

- Fuel Systems: Fuel pumps, regulators, and AN plumbing components

- ARP Fasteners: High-strength oil pan studs and engine fasteners

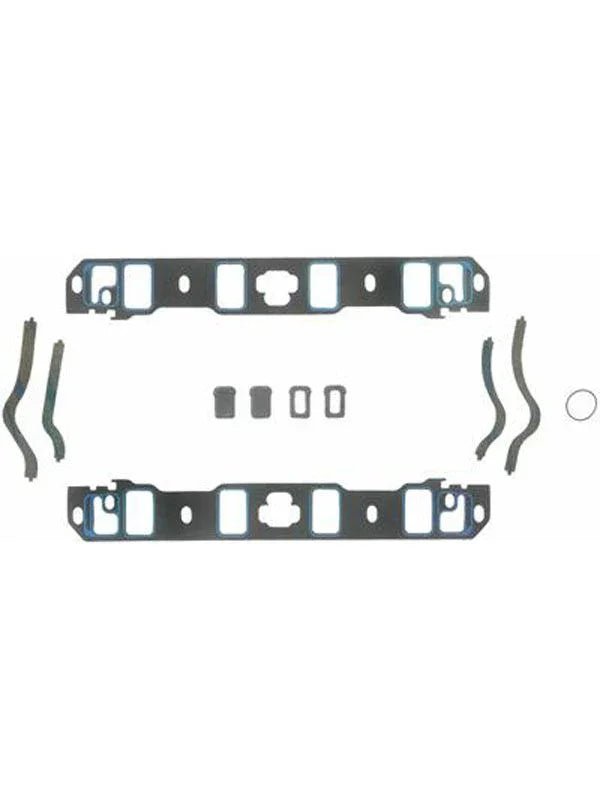

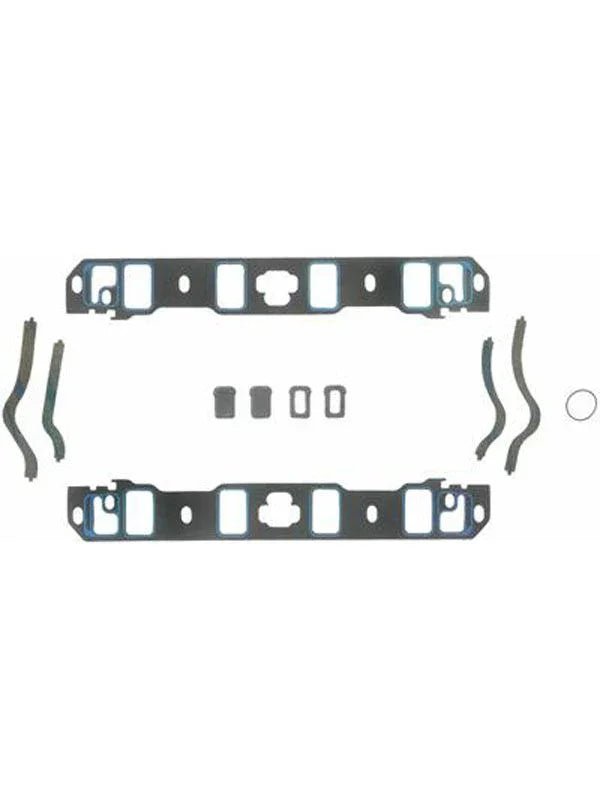

- Gaskets: Oil pan gaskets and complete gasket sets

Fast Shipping Across Australia - Same-day dispatch on orders placed before 2 PM AWST.

-

Proflow Ultra Pro Oil Cooler Kit 19 Row Dual Fan 625 CFM AN10 ORB Aluminium Black - PFEOC19-DF

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $402.45 AUDRegular price -

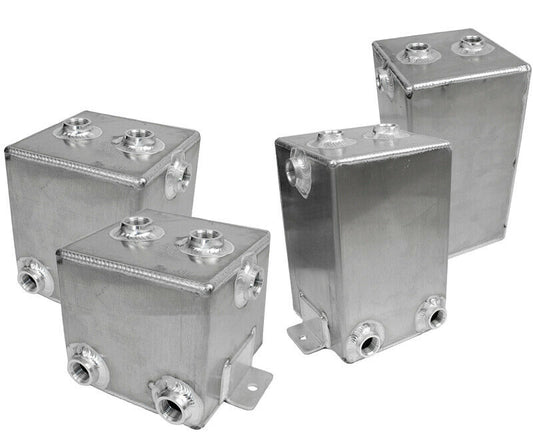

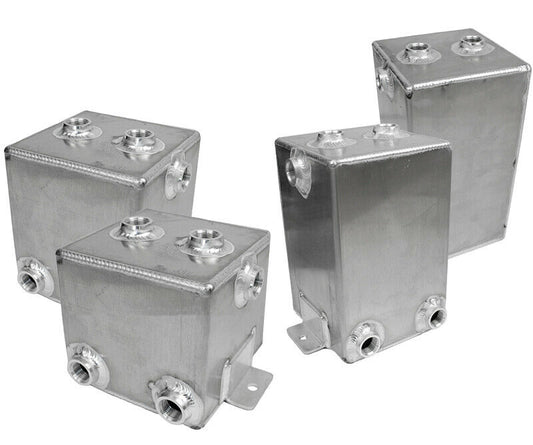

Proflow Oil Breather Catch Can - 1L Square Aluminium Polished Filtered Universal | PFECC1-P

Vendor:SS Racetech Rods & CustomsRegular price $199.20 AUDRegular price -

Proflow Oil Breather Catch Can - 1L Square Aluminium Black Filtered Universal | PFECC1-BK

Vendor:SS Racetech Rods & CustomsRegular price $199.20 AUDRegular price -

Proflow Oil Breather Catch Can - 2L Square Aluminium Black Filtered Universal | PFECC2-BK

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $203.25 AUDRegular price -

Proflow Oil Breather Catch Can - 3L Square Aluminium Black Filtered Universal | PFECC3-BK

Vendor:SS Racetech Rods & Customs2 reviews5.0 / 5.0

(2) 2 total reviews

Regular price $233.15 AUDRegular price -

Proflow Billet Aluminium Oil Breather Filter - 8AN Female Thread 90x65mm Black | PFECCB-3BK

Vendor:SS Racetech Rods & CustomsRegular price $66.25 AUDRegular price -

Proflow Billet Aluminium Oil Breather Filter - 10AN Female Thread 90x78mm Black | PFECCB-4BK

Vendor:SS Racetech Rods & CustomsRegular price $83.50 AUDRegular price -

Proflow Push-In Breather Cap - Steel Black 2-3/4" Diameter 1" Neck | PFE-R4870BK

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $25.60 AUDRegular price -

Proflow Push-In Breather Cap - Ball-Milled Polished Aluminium 2-3/4" Diameter | PFE-R8498

Vendor:SS Racetech Rods & CustomsRegular price $78.80 AUDRegular price -

Proflow Valve Cover Breather Cap Grommet - 1.25" OD x 1" ID Neoprene Baffled | PFE-R4996

Vendor:SS Racetech Rods & CustomsRegular price $15.00 AUDRegular price -

Proflow Fabricated Aluminium Square Tank - 3L Natural Universal Surge/Breather | PFEUT3

Vendor:SS Racetech Rods & CustomsRegular price $175.00 AUDRegular price -

Proflow Fabricated Aluminium Square Tank - 4L Natural Universal Surge/Breather | PFEUT4

Vendor:SS Racetech Rods & CustomsRegular price $188.00 AUDRegular price -

Proflow LS Engine Dipstick Braided Stainless Black - Billet Handle Holden Commodore LS1/LS2/LS3 (PFE-XED-5008)

Vendor:SS Racetech Rods & CustomsRegular price $153.15 AUDRegular price -

Proflow Engine Dipstick - Braided Steel Aluminium Black Holden 253/308 Late VN | PFE-XED-5028

Vendor:SS Racetech Rods & CustomsRegular price $140.00 AUDRegular price -

Proflow Braided Stainless Steel Engine Dipstick - Holden V8 253 308 Commodore VB-VL - PFE-XED-5024

Vendor:SS Racetech Rods & CustomsRegular price $140.00 AUDRegular price -

RTS-2101 RTS Oil Pan, For Holden V8 253-308, 355 Stroker, Steel, Black, 6.5 LT Capacity, Early Holden, Torana, each

Vendor:SS Racetech Rods & CustomsRegular price $363.95 AUDRegular price -

RTS Super Stroker Oil Pan - Small Block Chev 427 Stroker HQ-WB Holden - Windage Tray & Scraper - RTS-2201-SHP

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $430.00 AUDRegular price -

RTS-2002 RTS Oil Pan, SB For Ford 289,302W ,347 Stroker , Steel Black, 6.5 lt ,Windage Tray, suit early Falcon, each

Vendor:SS Racetech Rods & CustomsRegular price $327.00 AUDRegular price -

RTS-2001 RTS Oil Pan, SB For Ford 302-351C ,408 Stroker , Steel Black, 6.5 lt ,Windage Tray, suit early Falcon, each

Vendor:SS Racetech Rods & CustomsRegular price $327.00 AUDRegular price -

RTS-2201 RTS Oil Pan, SB Chev, 427 Stroker, Steel, Black, Windage Tray, Crank Scraper, Suit HQ-WB Holden, Each

Vendor:SS Racetech Rods & CustomsRegular price $329.00 AUDRegular price -

RTS-2102 RTS Oil Pan, For Holden V8 253-308, 355 Stroker, Steel, Black, 6.5 lt Capacity, Early Holden Commodore

Vendor:SS Racetech Rods & CustomsRegular price $342.00 AUDRegular price -

Proflow Oil Pan Gasket 1-Piece Rubber Aluminium Core - LS1/LS2/LS3 Holden Commodore (PFEGK6108)

Vendor:SS Racetech Rods & CustomsRegular price $47.50 AUDRegular price -

RTS-3318 RTS Oil Pump Pick Up, High Volume, For Holden HQ-WB, LH-UC Rear Sump For Holden V8

Vendor:SS Racetech Rods & CustomsRegular price $157.95 AUDRegular price -

Currently Unavailable

Currently UnavailableRTS-3317 RTS Oil Pump Pick Up, High Volume, Commodore VB-VT Front Sump For Holden V8

Vendor:SS Racetech Rods & CustomsRegular price $150.45 AUDRegular price

-

Air Filters - High-Flow Performance & Reusable Filters

High-Performance Air Filters - Washable, Reusable & High-Flow Maximize engine performance and...

-

Alternators & Accessories - High-Output Alternators & Brackets

Alternators & Accessories - High-Output Alternators & Mounting Brackets Upgrade your vehicle's...

-

Speedflow Hose - Braided Stainless Hose for Fuel, Oil & Brake

Premium Speedflow Braided Hose - Fuel, Oil, Coolant & Brake Lines Complete...

-

Speedflow Fittings

Premium Speedflow AN Fittings, Hose Ends & Adapters for High-Performance Plumbing Complete...

-

Engine Accessories - Performance Parts & Upgrades

Premium Engine Accessories - Performance Parts for Custom Builds & Motorsport Upgrade...

-

Fabrication Parts - Exhaust, Mandrel Bends & Weld Fittings

Premium Fabrication Parts - Custom Exhaust, Intake & Chassis Components Complete your...

-

🚨 On Sale & Clearance stock 🚨

Current Package deals at SS Racetech Rods & Customs🔥click here! Shop SS...

-

SS Racetech New Arrivals Featuring Holley Carburetor Parts

Explore the newest arrivals at SS Racetech featuring Holley small parts...

-

ARP Fasteners - Head Studs, Main Studs & Rod Bolts

ARP Fasteners - Premium Head Studs, Main Studs & Engine Bolts Build...

-

Fuel Systems - Fuel Pumps, Regulators & AN Fittings

📋 Fuel System Plumbing Guide → Download our complete fuel system plumbing...

-

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps Upgrade...

-

Stainless Steel & Aluminium Bends and Tube

Premium Mandrel Bends & Tube for Custom Exhaust Fabrication Professional-grade stainless steel...

-

Racing Seats

Shop Proforce Safety racing seats at SS Racetech Rods & Customs. Experience...

-

Safety Equipment - Quick Release Latches & Bonnet Pins

Safety Equipment - Quick Release Latches, Bonnet Pins & Racing Safety Ensure...

-

Suspension - Uniball Bearings, Rod Ends & Bushings

Premium Suspension Components - Uniball Bearings, Rod Ends & Bushings Upgrade your...

-

Rod Ends & Uniballs - FK Heim Joints

Premium Rod Ends, Uniballs & Heim Joints for Steering & Suspension High-performance...

-

Carburetors & Accessories - Spacers, Studs & Fuel Line Kits

Carburetors & Accessories - Spacers, Mounting Hardware & Fuel Lines Optimize your...

-

Gaskets - Intake, Exhaust & Engine Gasket Sets

Premium Engine Gaskets - Intake, Exhaust & Complete Gasket Sets Ensure leak-free...

-

Forced Induction

Forced Induction - Turbocharger Parts & AccessoriesPremium forced induction components for turbocharged...

-

Proflow Intake Manifolds - LS Holden Ford

High-Performance Proflow Intake Manifolds for LS, Holden & Ford EnginesUnlock peak engine...

-

Fuel Injection, Throttle Body's & Fuel Rails

Fuel Injection, Throttle Bodies & Fuel Rails – Precise Fuel Delivery for...

-

Cooling Systems - Oil Coolers, Transmission Coolers & Water Pumps

High-Performance Cooling Systems - Oil Coolers, Transmission Coolers & Heat Management Keep...

-

Drivetrain Components - Transmission & Driveline Parts

High-Performance Drivetrain, Transmission & Driveline ComponentsPremium drivetrain parts for reliable power transfer...

-

Race Suits / Apparel - Order in available!

Order in available! (We want to supply you with the newest dates...

-

Shocks & Springs

Fox bypass kit, Shaft, Bottom eyelet, King shocks rebuild kit, Fox mounting...

-

Silicone Hose, Bends and Reducers

Premium Silicone Hoses, Bends, Reducers & Brake Duct Hose SS Racetech stocks...

-

Steering & Shifters - Steering Columns & U-Joints

Steering & Shifters - Precision Control Components for Custom Builds Upgrade your...

-

Bearings & Seals

This collection offers Timken bearings, set 38, and oil seals. Find tapered...

-

Lubricants & Chemicals

Shop top-quality multi-purpose lubricant for cars and other high-performance automotive chemicals. Keep...

-

Electrical Components - Ignition, Alternators & Wiring

High-Performance Electrical Components - Ignition Systems, Alternators & Wiring Upgrade your vehicle's...

-

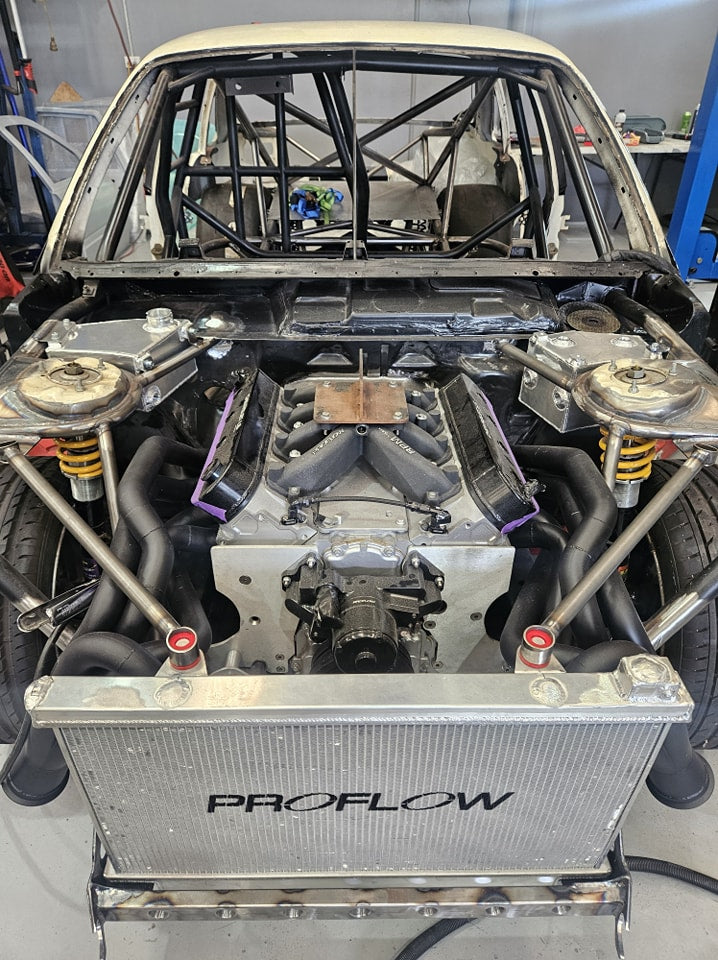

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds...

-

Custom Engines - Engine Rebuilds & Performance Builds

Custom Engine Builds - Rebuilds, Performance Upgrades & Complete Engines Unlock your...

-

Metric & Imperial Fasteners

SS Racetech Rods & Customs is your trusted source for...

-

Tyres & Wheels

Performance Tyres & Wheels for Race Cars & Street Machines High-performance tyres...

-

Drives & Pulleys - Performance Pulleys & Belt Tensioners

Drives & Pulleys - Performance Pulleys & Belt Tensioners Optimize your engine's...

Premium Oil Systems Collection for Performance & Reliability

At SS Racetech Rods & Customs, our Oil Systems Collection is engineered to deliver superior engine lubrication, cooling, and pressure management for your high-performance or classic build. Whether you’re upgrading your engine oil system, installing a remote oil filter kit, or enhancing your oil cooling system, we stock the best parts to keep your motor running clean and cool under all conditions.

Shop Quality Oil System Parts & Components

From durable oil pumps and oil cooler fittings to reliable oil filter housings and oil thermostats, our range covers every essential element of your vehicle’s engine lubrication system. We specialise in high-performance oil system upgrades designed to boost oil flow, improve cooling efficiency, and maintain stable engine oil pressure.

Performance Oil Pumps & Remote Filter Kits

Upgrade your ride with our selection of high-flow oil pumps and external oil pumps that provide superior lubrication for race, street rod, and custom builds. Pair them with our remote oil filter kits and oil filter relocation kits for convenient maintenance and better engine bay organisation.

Efficient Oil Cooling Solutions

Prevent overheating and extend engine life with our high-quality oil coolers and thermostatic oil cooler adapters. Designed to fit a variety of builds including LS swaps, V8s, and hot rods, our oil cooling products ensure optimal temperature control even under demanding driving conditions.

Precision Oil Fittings & Hose Kits

Complete your oil system upgrade with our extensive range of AN oil fittings, oil feed and return fittings, and heat-resistant oil hoses. Our fittings and hoses are crafted for durability and leak-free performance, perfect for custom oil plumbing in any engine bay.

Ideal for Hot Rods, Customs & Classic Builds

Our hot rod oil system parts, LS oil system upgrades, and performance V8 oil pumps are built with passion and precision. Whether restoring a classic or building a modern muscle machine, SS Racetech Rods & Customs provides parts trusted by professional builders and enthusiasts alike.

Why Choose SS Racetech Rods & Customs?

-

Extensive range of engine oil system parts and accessories

-

Premium-quality components designed for performance and durability

-

Fast Australian shipping and expert customer support

-

Trusted by builders across Australia for race, street, and custom applications