Collection: Alternators & Accessories - High-Output Alternators & Brackets

Alternators & Accessories - High-Output Alternators & Mounting Brackets

Upgrade your vehicle's charging system with our comprehensive range of high-output alternators and accessories designed for Australian V8 conversions, street machines, and custom builds. From 100-200+ amp alternators to billet mounting brackets and pulleys, we stock everything you need for reliable electrical power in high-demand applications.

High-Output Alternators

- 100-140 Amp Alternators: High-output alternators for street performance builds with electric fans, fuel pumps, and accessories

- One-Wire Alternators: Simplified wiring alternators requiring only battery connection for easy installation

- Internally Regulated Alternators: Self-contained voltage regulation for reliable charging

- Polished & Chrome Alternators: Show-quality finishes for engine bay presentation

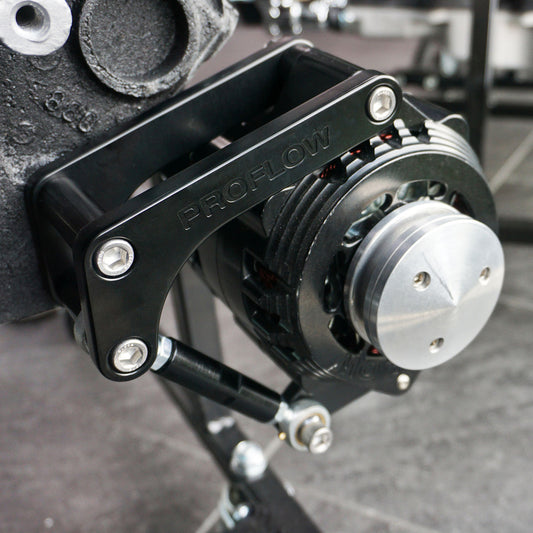

Alternator Mounting Brackets

- Alternator Brackets: Billet aluminium and steel mounting brackets for small block Chevy, big block Chevy, LS, and Ford engines

- Adjustable Brackets: Slotted brackets for belt tension adjustment and alternator positioning

- Low-Mount Brackets: Relocated alternator brackets for custom engine bay clearance

- Polished Brackets: Show-quality billet aluminium brackets for clean engine presentation

Related Electrical Components

Complete your charging system upgrade with complementary components:

- Electrical Components: Complete range of ignition, wiring, and electrical parts

- Drives & Pulleys: Performance pulleys and belt systems

- Engine Accessories: Complete range of performance engine components

Fast Shipping Across Australia - Same-day dispatch on orders placed before 2 PM AWST.

-

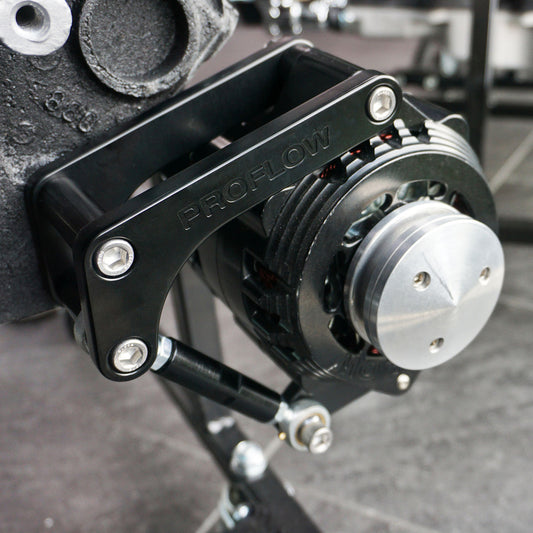

PFEABHOL01BK Proflow Alternator Bracket Kit, Aluminium For Holden V8 Drivers Side Mid Mount V8, Black

Vendor:SS Racetech Rods & CustomsRegular price $234.30 AUDRegular price -

PFEABHOL02BK Proflow Alternator Bracket Kit, Aluminium For Holden V8 Passengers Side Mid Mount V8, Black

Vendor:SS Racetech Rods & CustomsRegular price $236.25 AUDRegular price -

PFEABHOL04BK Proflow Alternator Bracket Kit, Aluminium GM For Holden VT-VZ Commodore LS1 LS2, Black

Vendor:SS Racetech Rods & CustomsRegular price $227.70 AUDRegular price -

PFEABHOL05BK Proflow Alternator Bracket Kit, Aluminium GM For Holden VE-VF Commodore LS3/L92, Black

Vendor:SS Racetech Rods & CustomsRegular price $219.30 AUDRegular price -

PFEABSBC01-BK Proflow Alternator Bracket, For Chevrolet Small Block, Drivers Side, Long Water Pump, Mid Mount, Black Anodised

Vendor:SS Racetech Rods & CustomsRegular price $231.00 AUDRegular price -

PFEABSBC02BK Proflow Alternator Bracket, For Chevrolet Small Block, Passenger Side, Short Water Pump, Low Mount, Black Anodised

Vendor:SS Racetech Rods & CustomsRegular price $236.25 AUDRegular price -

PFEABWIND01BK Proflow Alternator Bracket, For Ford V8 Windsor 351W, Drivers Side Mid Mount, Polished Black

Vendor:SS Racetech Rods & CustomsRegular price $234.65 AUDRegular price -

PFEPM37127BKW Proflow Alternator Power Spark, 100 Amp 1-Wire, Internal Regulator, Black Wrinkle, V-Belt, Chev, For Holden, Commodore, Torana, Each

Vendor:SS Racetech Rods & CustomsRegular price $245.00 AUDRegular price -

PFEPM37141BKW Proflow Alternator Power Spark, 140 Amp 1-Wire, Internal Regulator, Black Wrinkle, V-Belt, For Ford, Falcon, Each

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $297.75 AUDRegular price -

PFEPM37293BKW Alternator Power Spark, 140 Amp 1-Wire, Internal Regulator, Black Powder coat, V-Belt, Chev, Holden, Commodore, Torana, Each

Vendor:SS Racetech Rods & CustomsRegular price $292.75 AUDRegular price -

PFEPM38247BK Proflow Alternator Power Spark, 140 Amp, For Holden Commodore LS VT, VX, VY, Internal Regulator, Black Serpentine Pulley, Each

Vendor:SS Racetech Rods & CustomsRegular price $411.50 AUDRegular price -

PFEPM38270BK Proflow Alternator Power Spark, 140 Amp, For Holden Commodore LS VE/VF, Internal Regulator, Black, Serpentine Pulley

Vendor:SS Racetech Rods & CustomsRegular price $394.75 AUDRegular price -

Proflow Power Spark Alternator 140 Amp 1-Wire Chrome - V-Belt Chevy Holden Commodore (PFEPM37293)

Vendor:SS Racetech Rods & CustomsRegular price $275.00 AUDRegular price

-

Air Filters - High-Flow Performance & Reusable Filters

High-Performance Air Filters - Washable, Reusable & High-Flow Maximize engine performance and...

-

Alternators & Accessories - High-Output Alternators & Brackets

Alternators & Accessories - High-Output Alternators & Mounting Brackets Upgrade your vehicle's...

-

Speedflow Hose - Braided Stainless Hose for Fuel, Oil & Brake

Premium Speedflow Braided Hose - Fuel, Oil, Coolant & Brake Lines Complete...

-

Speedflow Fittings

Premium Speedflow AN Fittings, Hose Ends & Adapters for High-Performance Plumbing Complete...

-

Engine Accessories - Performance Parts & Upgrades

Premium Engine Accessories - Performance Parts for Custom Builds & Motorsport Upgrade...

-

Fabrication Parts - Exhaust, Mandrel Bends & Weld Fittings

Premium Fabrication Parts - Custom Exhaust, Intake & Chassis Components Complete your...

-

🚨 On Sale & Clearance stock 🚨

Current Package deals at SS Racetech Rods & Customs🔥click here! Shop SS...

-

SS Racetech New Arrivals Featuring Holley Carburetor Parts

Explore the newest arrivals at SS Racetech featuring Holley small parts...

-

ARP Fasteners - Head Studs, Main Studs & Rod Bolts

ARP Fasteners - Premium Head Studs, Main Studs & Engine Bolts Build...

-

Fuel Systems - Fuel Pumps, Regulators & AN Fittings

📋 Fuel System Plumbing Guide → Download our complete fuel system plumbing...

-

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps Upgrade...

-

Stainless Steel & Aluminium Bends and Tube

Premium Mandrel Bends & Tube for Custom Exhaust Fabrication Professional-grade stainless steel...

-

Racing Seats

Shop Proforce Safety racing seats at SS Racetech Rods & Customs. Experience...

-

Safety Equipment - Quick Release Latches & Bonnet Pins

Safety Equipment - Quick Release Latches, Bonnet Pins & Racing Safety Ensure...

-

Suspension - Uniball Bearings, Rod Ends & Bushings

Premium Suspension Components - Uniball Bearings, Rod Ends & Bushings Upgrade your...

-

Rod Ends & Uniballs - FK Heim Joints

Premium Rod Ends, Uniballs & Heim Joints for Steering & Suspension High-performance...

-

Carburetors & Accessories - Spacers, Studs & Fuel Line Kits

Carburetors & Accessories - Spacers, Mounting Hardware & Fuel Lines Optimize your...

-

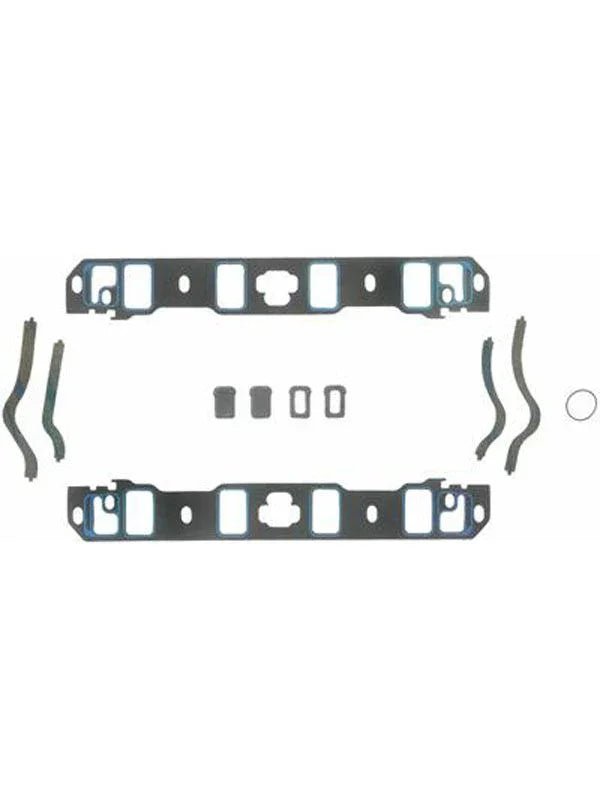

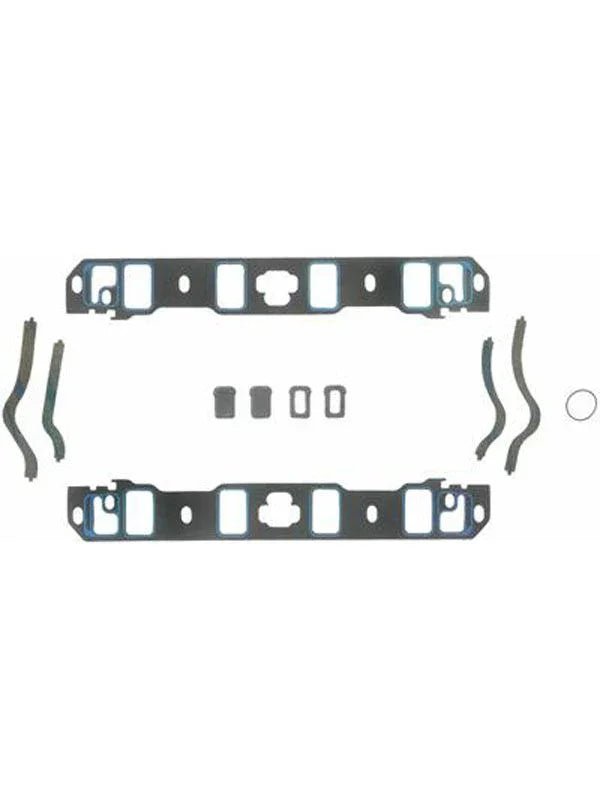

Gaskets - Intake, Exhaust & Engine Gasket Sets

Premium Engine Gaskets - Intake, Exhaust & Complete Gasket Sets Ensure leak-free...

-

Forced Induction

Forced Induction - Turbocharger Parts & AccessoriesPremium forced induction components for turbocharged...

-

Proflow Intake Manifolds - LS Holden Ford

High-Performance Proflow Intake Manifolds for LS, Holden & Ford EnginesUnlock peak engine...

-

Fuel Injection, Throttle Body's & Fuel Rails

Fuel Injection, Throttle Bodies & Fuel Rails – Precise Fuel Delivery for...

-

Cooling Systems - Oil Coolers, Transmission Coolers & Water Pumps

High-Performance Cooling Systems - Oil Coolers, Transmission Coolers & Heat Management Keep...

-

Drivetrain Components - Transmission & Driveline Parts

High-Performance Drivetrain, Transmission & Driveline Components Premium drivetrain parts for reliable power...

-

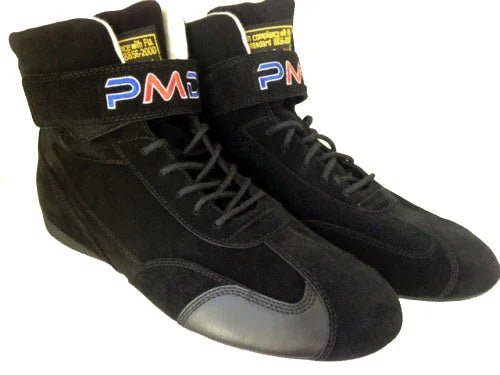

Race Suits / Apparel - Order in available!

Order in available! (We want to supply you with the newest dates...

-

Shocks & Springs

Fox bypass kit, Shaft, Bottom eyelet, King shocks rebuild kit, Fox mounting...

-

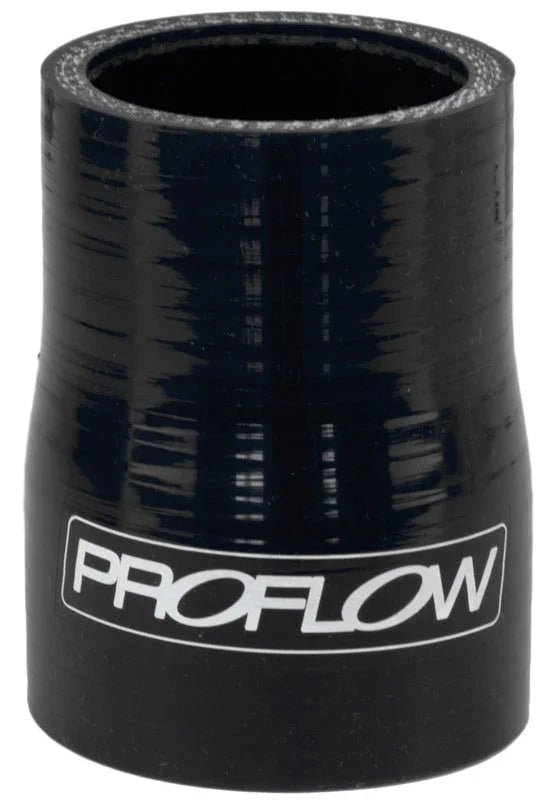

Silicone Hose, Bends and Reducers

Premium Silicone Hoses, Bends, Reducers & Brake Duct Hose SS Racetech stocks...

-

Steering & Shifters - Steering Columns & U-Joints

Steering & Shifters - Precision Control Components for Custom Builds Upgrade your...

-

Bearings & Seals

This collection offers Timken bearings, set 38, and oil seals. Find tapered...

-

Lubricants & Chemicals

Shop top-quality multi-purpose lubricant for cars and other high-performance automotive chemicals. Keep...

-

Electrical Components - Ignition, Alternators & Wiring

High-Performance Electrical Components - Ignition Systems, Alternators & Wiring Upgrade your vehicle's...

-

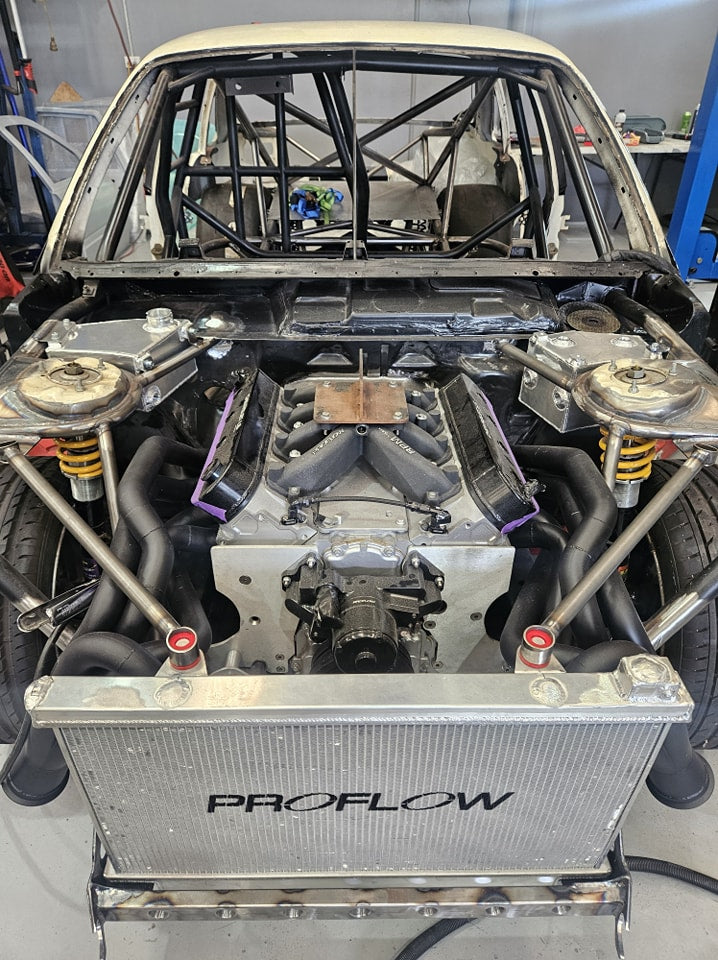

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds...

-

Custom Engines - Engine Rebuilds & Performance Builds

Custom Engine Builds - Rebuilds, Performance Upgrades & Complete Engines Unlock your...

-

Metric & Imperial Fasteners

SS Racetech Rods & Customs is your trusted source for...

-

Tyres & Wheels

Performance Tyres & Wheels for Race Cars & Street Machines High-performance tyres...

-

Drives & Pulleys - Performance Pulleys & Belt Tensioners

Drives & Pulleys - Performance Pulleys & Belt Tensioners Optimize your engine's...