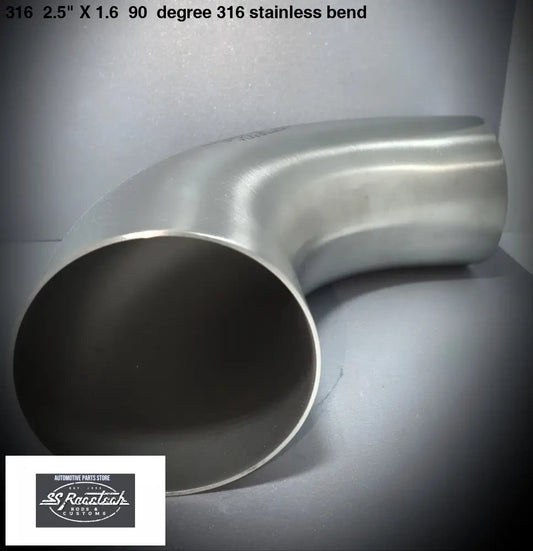

Collection: Stainless Steel & Aluminium Bends and Tube

Premium Mandrel Bends & Tube for Custom Exhaust Fabrication

Professional-grade stainless steel and aluminium bends, straight tube, and pie cuts for custom exhaust systems, intake piping, and fabrication projects.

- Mandrel bent for smooth flow and maximum performance

- Multiple sizes available - from 1.5" to 4" diameter

- Australian stock - fast Perth-based dispatch

- Perfect for turbo systems, exhaust builds, and custom fabrication

Shop by Material & Angle

Find the exact bend or tube you need for your custom exhaust or intake build:

- 316 stainless straight tube - Corrosion-resistant exhaust tubing in multiple diameters

- 316 stainless 90° elbows - Right angle exhaust bends

- 316 stainless 45° elbows - Standard angle exhaust bends

- Aluminium straight tube - Lightweight intake piping

- Aluminium 90° bends - Intake and intercooler piping

- Aluminium 45° bends - Smooth flow intake bends

- Aluminium 30° bends - Gentle angle routing

- Oval exhaust tubing - Low-profile exhaust solutions

- Pie cuts - Custom angle fabrication pieces

Complete Your Exhaust Build

Building a custom exhaust system? You'll need more than just bends and tube:

- V-band clamps - Quick-release exhaust connections

- Mufflers - Racecraft stainless steel mufflers and resonators

- Exhaust wrap - Heat management and protection

- Weld-in tube clamp connectors - Professional tube joining solutions

- View all fabrication parts - Complete range for custom builds

Trusted by fabricators, race teams, and performance enthusiasts across Australia.

-

316 Stainless Steel Bend 1 Inch 90 Degree - 1.6mm Wall (25mm)

Vendor:SS Racetech Rods & CustomsRegular price $14.50 AUDRegular price -

316 1 1/4" X 1.6 90 degree 316 stainless bend

Vendor:SS Racetech Rods & CustomsRegular price $19.50 AUDRegular price -

316 Stainless Steel Bend 1.75 Inch 90 Degree - 1.6mm Wall (45mm)

Vendor:SS Racetech Rods & CustomsRegular price $43.50 AUDRegular price -

316 Stainless Steel Bend 1.5 Inch 90 Degree - 1.6mm Wall (38mm)

Vendor:SS Racetech Rods & CustomsRegular price $18.50 AUDRegular price -

316 Stainless Steel Bend 2 Inch 90 Degree - 1.6mm Wall (51mm)

Vendor:SS Racetech Rods & CustomsRegular price $28.00 AUDRegular price -

316 Stainless Steel Bend 2.5 Inch 90 Degree - 1.6mm Wall (63mm)

Vendor:SS Racetech Rods & CustomsRegular price $43.50 AUDRegular price -

316 Stainless Steel Bend 3 Inch 90 Degree - 1.6mm Wall (76mm)

Vendor:SS Racetech Rods & CustomsRegular price $58.50 AUDRegular price -

316 Stainless Steel Bend 3.5 Inch 90 Degree - 1.6mm Wall (89mm)

Vendor:SS Racetech Rods & CustomsRegular price $49.50 AUDRegular price -

316 Stainless Steel Bend 4 Inch 90 Degree - 1.6mm Wall (102mm)

Vendor:SS Racetech Rods & CustomsRegular price $61.60 AUDRegular price -

316 Stainless Steel Bend 1.5 Inch 45 Degree - 1.6mm Wall (38mm)

Vendor:SS Racetech Rods & CustomsRegular price $17.00 AUDRegular price -

316 Stainless Steel Bend 2 Inch 45 Degree - 1.6mm Wall (51mm)

Vendor:SS Racetech Rods & CustomsRegular price $23.00 AUDRegular price -

316 Stainless Steel Bend 2.5 Inch 45 Degree - 1.6mm Wall (63mm)

Vendor:SS Racetech Rods & Customs2 reviews5.0 / 5.0

(2) 2 total reviews

Regular price $34.00 AUDRegular price -

316 Stainless Steel Bend 3 Inch 45 Degree - 1.6mm Wall (76mm)

Vendor:SS Racetech Rods & CustomsRegular price $46.00 AUDRegular price -

Proflow Aluminium Straight Tube 1.00" x 100cm - PFEAP101-100L

Vendor:SS Racetech Rods & CustomsRegular price $55.55 AUDRegular price -

Proflow Aluminium Tubing 1.00" Straight 30cm - Air Intake Intercooler (PFEAP101-100)

Vendor:SS Racetech Rods & CustomsRegular price $33.55 AUDRegular price -

Proflow Aluminium Straight Tube 1.25" x 100cm - PFEAP101-125L

Vendor:SS Racetech Rods & CustomsRegular price $55.30 AUDRegular price -

Proflow Aluminium Tubing 1.25" Straight 30cm - Air Intake Intercooler (PFEAP101-125)

Vendor:SS Racetech Rods & CustomsRegular price $32.65 AUDRegular price -

Proflow Aluminium Straight Tube 1.50" x 100cm - PFEAP101-150L

Vendor:SS Racetech Rods & CustomsRegular price $57.10 AUDRegular price -

Proflow Aluminium Tubing 1.50" Straight 30cm - Air Intake Intercooler (PFEAP101-150)

Vendor:SS Racetech Rods & CustomsRegular price $32.65 AUDRegular price -

Proflow Aluminium Straight Tube 1.75" x 100cm - PFEAP101-175L

Vendor:SS Racetech Rods & CustomsRegular price $55.30 AUDRegular price -

Proflow Aluminium Tubing 1.75" Straight 30cm - Air Intake Intercooler (PFEAP101-175)

Vendor:SS Racetech Rods & CustomsRegular price $32.65 AUDRegular price -

Proflow Aluminium Straight Tube 2." x 100cm - PFEAP101-200L

Vendor:SS Racetech Rods & CustomsRegular price $59.80 AUDRegular price$62.00 AUDSale price $59.80 AUDSale -

Proflow Aluminium Straight Tube 2.50" x 100cm - PFEAP101-250L

Vendor:SS Racetech Rods & CustomsRegular price $59.80 AUDRegular price -

Proflow Aluminium Tubing Air Intake, Intercooler 2.75in. Straight 30cm Long - PFEAP101-275

Vendor:SS Racetech Rods & CustomsRegular price $32.45 AUDRegular price

Have a question?

Stainless & Aluminium FAQ

What makes your stainless and aluminium bends and tubing ideal for custom automotive projects?

Our stainless and aluminium bends and tubing are engineered specifically for custom automotive fabrication. Made from premium 316-grade stainless steel and high-quality aluminium, they offer exceptional corrosion resistance, system reliability, and optimal fluid flow. These materials are lightweight and durable, perfect for building or upgrading exhaust, intake, or coolant systems. Whether you're a racing enthusiast or working on a classic car restoration, our range of bend angles and tube lengths gives you the flexibility and quality you need for a professional finish.

How do I choose between stainless steel and aluminium bends for my application?

Choosing between stainless and aluminium bends depends on your project's specific needs. 316-grade stainless steel bends and tubes are best if you need maximum corrosion resistance and strength, like in exhaust systems or high-temperature applications. Aluminium bends and tubes are lighter, making them excellent for intake and coolant systems where weight savings matter. Both options are durable, but if you're working in an environment with extreme heat or exposure to harsh elements, stainless steel may be the better option. If you need help matching the right material to your project, our team is happy to offer guidance!

Are your tube bends compatible with other Proflow and standard automotive components?

Absolutely! Our stainless and aluminium bends and tubing are designed to be compatible with Proflow aluminium tubing and most standard exhaust and intake components. The outer diameters and wall thicknesses meet common automotive fabrication standards, so you can use them seamlessly with a wide variety of clamps, couplings, and joiners. If you need specific sizing information to ensure a perfect fit, please check each product's detailed specifications or contact us for advice.

Can I install these stainless and aluminium bends and tubes myself, or do I need a professional?

Our bends and tubing are designed with both professional fabricators and DIY automotive enthusiasts in mind. With basic fabrication tools such as a tube cutter, a welder (for stainless), and appropriate joiners or silicone couplers (for aluminium), you can install these parts in your custom setup. If you're comfortable with automotive fabrication, installation should be straightforward. For high-precision applications or complex systems, professional installation is recommended to ensure proper sealing and alignment.

How durable are your stainless and aluminium bends and tubes for long-term automotive use?

Durability is one of our top priorities. Our 316 stainless steel tubing is highly resistant to rust, heat, and chemicals, making it ideal for demanding automotive environments and long-term performance. The aluminium bends and tubes, while lighter, also offer excellent corrosion resistance and strength, especially in less extreme environments. When installed correctly, both materials provide reliable performance and maintain their looks over time, giving you peace of mind and lasting value for your custom fabrication project.

-

Air Filters - High-Flow Performance & Reusable Filters

High-Performance Air Filters - Washable, Reusable & High-Flow Maximize engine performance and...

-

Alternators & Accessories - High-Output Alternators & Brackets

Alternators & Accessories - High-Output Alternators & Mounting Brackets Upgrade your vehicle's...

-

Speedflow Hose - Braided Stainless Hose for Fuel, Oil & Brake

Premium Speedflow Braided Hose - Fuel, Oil, Coolant & Brake Lines Complete...

-

Speedflow Fittings

Premium Speedflow AN Fittings, Hose Ends & Adapters for High-Performance Plumbing Complete...

-

Engine Accessories - Performance Parts & Upgrades

Premium Engine Accessories - Performance Parts for Custom Builds & Motorsport Upgrade...

-

Fabrication Parts - Exhaust, Mandrel Bends & Weld Fittings

Premium Fabrication Parts - Custom Exhaust, Intake & Chassis Components Complete your...

-

ARP Fasteners - Head Studs, Main Studs & Rod Bolts

ARP Fasteners - Premium Head Studs, Main Studs & Engine Bolts Build...

-

Fuel Systems - Fuel Pumps, Regulators & AN Fittings

📋 Fuel System Plumbing Guide → Download our complete fuel system plumbing...

-

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps Upgrade...

-

Stainless Steel & Aluminium Bends and Tube

Premium Mandrel Bends & Tube for Custom Exhaust Fabrication Professional-grade stainless steel...

-

Racing Seats

Shop Proforce Safety racing seats at SS Racetech Rods & Customs. Experience...

-

Safety Equipment - Quick Release Latches & Bonnet Pins

Safety Equipment - Quick Release Latches, Bonnet Pins & Racing Safety Ensure...

-

Suspension - Uniball Bearings, Rod Ends & Bushings

Premium Suspension Components - Uniball Bearings, Rod Ends & Bushings Upgrade your...

-

Rod Ends & Uniballs - FK Heim Joints

Premium Rod Ends, Uniballs & Heim Joints for Steering & Suspension High-performance...

-

Carburetors & Accessories - Spacers, Studs & Fuel Line Kits

Carburetors & Accessories - Spacers, Mounting Hardware & Fuel Lines Optimize your...

-

Gaskets - Intake, Exhaust & Engine Gasket Sets

Engine Gaskets - Intake, Exhaust & Complete Gasket Sets High-quality gaskets for...

-

Forced Induction

Forced Induction - Turbocharger Parts & AccessoriesPremium forced induction components for turbocharged...

-

Proflow Intake Manifolds - LS Holden Ford

High-Performance Proflow Intake Manifolds for LS, Holden & Ford EnginesUnlock peak engine...

-

Fuel Injection, Throttle Body's & Fuel Rails

Fuel Injection, Throttle Bodies & Fuel Rails – Precise Fuel Delivery for...

-

Cooling Systems - Oil Coolers, Transmission Coolers & Water Pumps

High-Performance Cooling Systems - Oil Coolers, Transmission Coolers & Heat Management Keep...

-

Race Suits / Apparel - Order in available!

Order in available! (We want to supply you with the newest dates...

-

Shocks & Springs

Fox bypass kit, Shaft, Bottom eyelet, King shocks rebuild kit, Fox mounting...

-

Silicone Hose, Bends and Reducers

Premium Silicone Hoses, Bends, Reducers & Brake Duct Hose SS Racetech stocks...

-

Steering & Shifters - Steering Columns & U-Joints

Steering & Shifters - Precision Control Components for Custom Builds Upgrade your...

-

Bearings & Seals

This collection offers Timken bearings, set 38, and oil seals. Find tapered...

-

Lubricants & Chemicals

Shop top-quality multi-purpose lubricant for cars and other high-performance automotive chemicals. Keep...

-

Electrical Components - Ignition, Alternators & Wiring

High-Performance Electrical Components - Ignition Systems, Alternators & Wiring Upgrade your vehicle's...

-

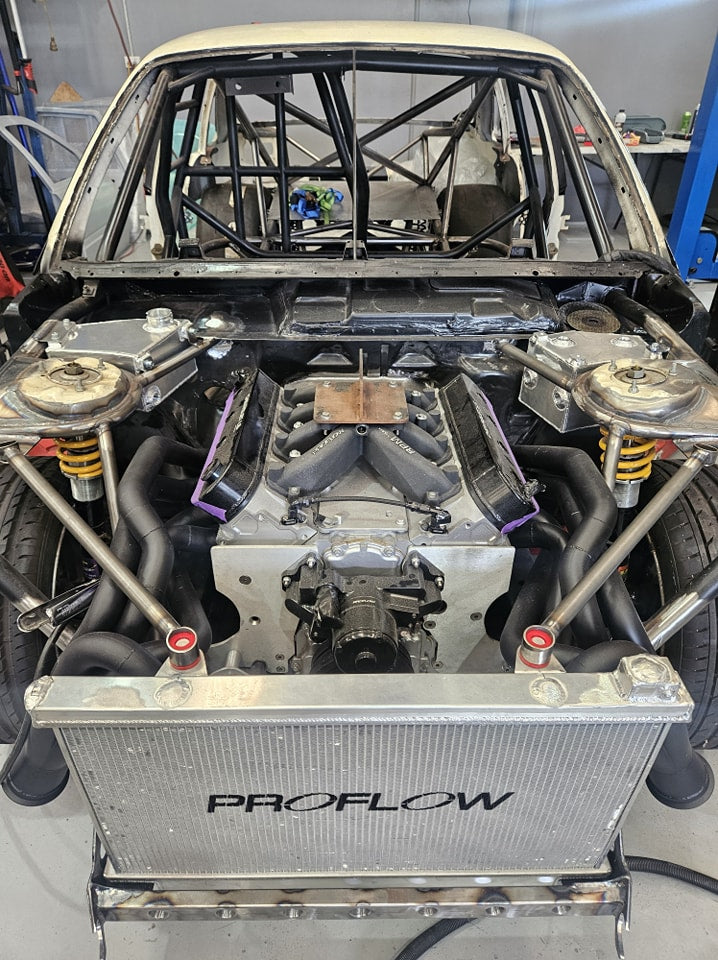

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds...

-

Custom Engines - Engine Rebuilds & Performance Builds

Custom Engine Builds - Rebuilds, Performance Upgrades & Complete Engines Unlock your...

-

Metric & Imperial Fasteners

SS Racetech Rods & Customs is your trusted source for...

-

Tyres & Wheels

Performance Tyres & Wheels for Race Cars & Street Machines High-performance tyres...

-

Drives & Pulleys - Performance Pulleys & Belt Tensioners

Drives & Pulleys - Performance Pulleys & Belt Tensioners Optimize your engine's...