Collection: Cooling Systems - Oil Coolers, Transmission Coolers & Water Pumps

High-Performance Cooling Systems - Oil Coolers, Transmission Coolers & Heat Management

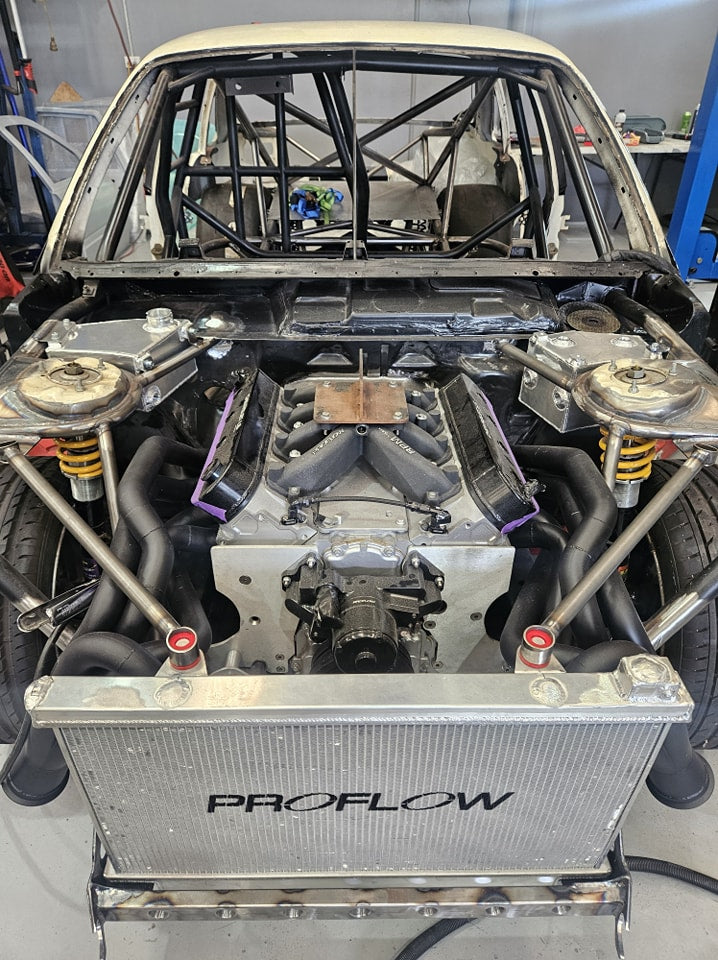

Keep your engine running at optimal temperatures with our comprehensive range of performance cooling systems designed for Australian street machines, race cars, and custom builds. From electric fans and water pumps to oil coolers, transmission coolers, and intercoolers, we stock everything you need for efficient heat management and reliable performance.

Engine Cooling Components

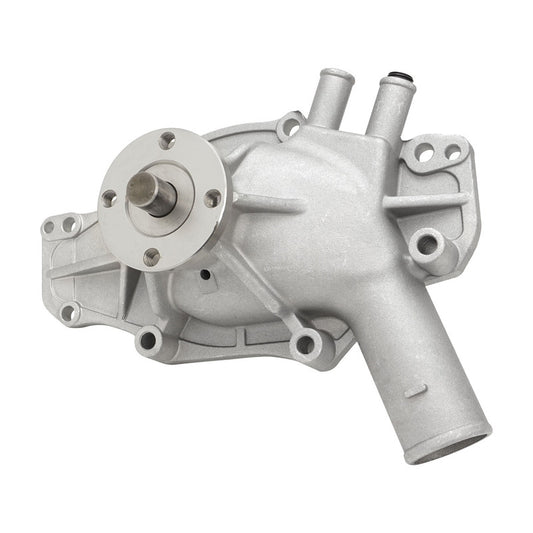

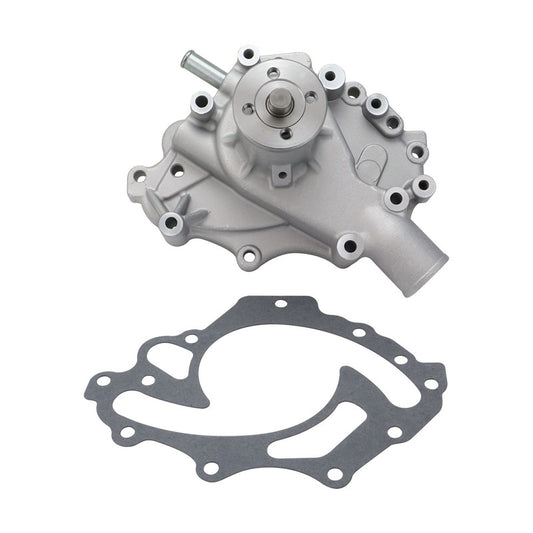

- Water Pumps: High-flow electric and mechanical water pumps for increased coolant circulation and superior cooling efficiency

- Electric Cooling Fans: High-CFM electric fans with slim profiles for improved airflow and reduced engine load compared to mechanical fans

- Radiator Caps: High-pressure radiator caps (16-32 PSI) to raise boiling point and maintain system pressure in performance applications

- Water Necks & Thermostat Housings: Billet aluminium coolant outlets and thermostat housings for custom cooling system plumbing

- Coolant Hoses & Fittings: Silicone hoses, AN fittings, and adapters for leak-free cooling system connections

- Overflow Tanks & Expansion Tanks: Aluminium and polished stainless catch cans for pressurized cooling systems

Cooling System Accessories

- Temperature Gauges & Sensors: Accurate monitoring of coolant, oil, and transmission temperatures

- Radiator Hose Adapters: AN to barb adapters and reducers for custom cooling system plumbing

Common Cooling System Applications

- V8 engine conversions requiring upgraded cooling capacity

- Turbo and supercharger builds with intercoolers

- Race car preparation and track day vehicles

- Towing and heavy-duty applications

- Hot climate operation and desert racing

- Engine swaps where factory components won't fit

- Show cars requiring polished or custom cooling components

Related Engine Components

Complete your cooling system upgrade with complementary components:

- Oil Systems: Oil pans, pumps, filters, and complete oil system components

- Speedflow AN Fittings: Complete range of AN hose ends and adapters for cooling system plumbing

- Weld Bungs: AN and ORB weld fittings for custom oil and coolant lines

- Aluminium Mandrel Bends: Custom intercooler piping and intake fabrication

- Engine Accessories: Complete range of performance engine components

. Fast shipping across Australia with same-day dispatch on orders placed before 2 PM AWST.

-

Proflow Billet Aluminium Swivel Water Neck - Black 45° Holden V8 253/308 | PFETH-801BK

Vendor:SS Racetech Rods & CustomsRegular price $165.10 AUDRegular price -

Proflow Billet Aluminium Swivel Water Neck - Black 45° SB/BB Chev | PFETH-806BK

Vendor:SS Racetech Rods & CustomsRegular price $158.10 AUDRegular price -

Proflow Billet Water Neck 45 Degree Swivel Black - SB Ford 289-351W (PFETH-804BK)

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $152.60 AUDRegular price -

Currently Unavailable

Currently UnavailableProflow Billet Aluminium Swivel Water Neck - Black 90° Holden LS1/LS2/LS3 | PFETH-808BK

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $154.70 AUDRegular price -

Proflow Billet Aluminium Swivel Water Neck - Silver 90° Holden LS1/LS2/LS3 | PFETH-808S

Vendor:SS Racetech Rods & CustomsRegular price $156.60 AUDRegular price -

Proflow Billet Aluminium Swivel Water Neck - Silver 90° SB Ford 302-351C | PFETH-802S

Vendor:SS Racetech Rods & CustomsRegular price $158.10 AUDRegular price -

Proflow Billet Water Neck 90 Degree Swivel Black - SB/BB Chev (PFETH-803BK)

Vendor:SS Racetech Rods & CustomsRegular price $149.60 AUDRegular price -

PFETH-803S Proflow Water Neck, Billet Aluminium Swivel, Silver Anodised, 90 Degree, SB & BB Chev

Vendor:SS Racetech Rods & CustomsRegular price $146.10 AUDRegular price -

Proflow Billet Aluminium Water Neck - Silver Straight SB Ford 302-351C | PFETH-805S

Vendor:SS Racetech Rods & CustomsRegular price $103.10 AUDRegular price -

Proflow Billet Aluminium Water Neck - Black Straight SB/BB Chev | PFETH-807BK

Vendor:SS Racetech Rods & CustomsRegular price $106.50 AUDRegular price -

Proflow Billet Aluminium Water Neck - Silver Straight SB/BB Chev | PFETH-807S

Vendor:SS Racetech Rods & CustomsRegular price $110.90 AUDRegular price -

Proflow Billet Aluminium Water Neck - Black Straight Holden Commodore LS1/LS2 | PFETH-812BK

Vendor:SS Racetech Rods & CustomsRegular price $115.50 AUDRegular price -

Proflow Electric Water Pump LS1 LS2 LS3 LSA - 132 LPM Cast Aluminium Black PFEBEW5509-CA

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $519.00 AUDRegular price -

Proflow Water Pump, Mechanical, Replacement, For Holden Commodore LS1 Dome Pulley, With Thermostat PFEWP-1005

Vendor:SS Racetech Rods & CustomsRegular price $243.50 AUDRegular price -

Proflow Water Pump, Mechanical, Replacement, For Holden Commodore VE VF LS2 LS3 6.0L 6.2L Driver side Flat Pulley - PFEWP-1006

Vendor:SS Racetech Rods & CustomsRegular price $263.30 AUDRegular price -

Proflow Water Pump Aluminium Holden V8 253 308 304 - Long Style Blue Black PFEWP-005

Vendor:SS Racetech Rods & CustomsRegular price $81.95 AUDRegular price -

Proflow Water Pump Aluminium Holden V8 253 308 - Short Style Red Blue PFEWP-0023

Vendor:SS Racetech Rods & CustomsRegular price $83.95 AUDRegular price -

Proflow Water Pump Aluminium SB Chevy Small Block - Short Style Satin PFEWP-9208

Vendor:SS Racetech Rods & CustomsRegular price $209.95 AUDRegular price -

Proflow Ultra Cool Water Pump - SB Chevy Short Style Black Aluminium (PFEWP-9208BK)

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $217.95 AUDRegular price -

Proflow Water Pump SB Ford 302 351 Cleveland 400M - Cast Aluminium Ultra Cool - PFEWP-8209

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $255.50 AUDRegular price -

Currently Unavailable

Currently UnavailableProflow Water Pump Aluminium SB Chevy Small Block - 8 Blade Long Style Satin PFEWP-9241

Vendor:SS Racetech Rods & CustomsRegular price $257.50 AUDRegular price -

Proflow Ultra Cool Water Pump - SB Chevy Long Style Satin Aluminium (PFEWP-9240)

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $287.25 AUDRegular price -

Proflow Water Pump Aluminium BB Chevy Big Block - 8 Blade Long Style Satin PFEWP-9243

Vendor:SS Racetech Rods & CustomsRegular price $298.80 AUDRegular price -

Proflow Ultra Cool Transmission Cooler Kit - 10" x 15.5" with 350 CFM Fan Natural Finish - PFETCF515

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $223.45 AUDRegular price

Shop by Engine

View all-

Air Filters - High-Flow Performance & Reusable Filters

High-Performance Air Filters - Washable, Reusable & High-Flow Maximize engine performance and...

-

Alternators & Accessories - High-Output Alternators & Brackets

Alternators & Accessories - High-Output Alternators & Mounting Brackets Upgrade your vehicle's...

-

Speedflow Hose - Braided Stainless Hose for Fuel, Oil & Brake

Premium Speedflow Braided Hose - Fuel, Oil, Coolant & Brake Lines Complete...

-

Speedflow Fittings

Premium Speedflow AN Fittings, Hose Ends & Adapters for High-Performance Plumbing Complete...

-

Engine Accessories - Performance Parts & Upgrades

Premium Engine Accessories - Performance Parts for Custom Builds & Motorsport Upgrade...

-

Fabrication Parts - Exhaust, Mandrel Bends & Weld Fittings

Premium Fabrication Parts - Custom Exhaust, Intake & Chassis Components Complete your...

-

ARP Fasteners - Head Studs, Main Studs & Rod Bolts

ARP Fasteners - Premium Head Studs, Main Studs & Engine Bolts Build...

-

Fuel Systems - Fuel Pumps, Regulators & AN Fittings

📋 Fuel System Plumbing Guide → Download our complete fuel system plumbing...

-

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps Upgrade...

-

Stainless Steel & Aluminium Bends and Tube

Premium Mandrel Bends & Tube for Custom Exhaust Fabrication Professional-grade stainless steel...

-

Racing Seats

Shop Proforce Safety racing seats at SS Racetech Rods & Customs. Experience...

-

Safety Equipment - Quick Release Latches & Bonnet Pins

Safety Equipment - Quick Release Latches, Bonnet Pins & Racing Safety Ensure...

-

Suspension - Uniball Bearings, Rod Ends & Bushings

Premium Suspension Components - Uniball Bearings, Rod Ends & Bushings Upgrade your...

-

Rod Ends & Uniballs - FK Heim Joints

Premium Rod Ends, Uniballs & Heim Joints for Steering & Suspension High-performance...

-

Carburetors & Accessories - Spacers, Studs & Fuel Line Kits

Carburetors & Accessories - Spacers, Mounting Hardware & Fuel Lines Optimize your...

-

Gaskets - Intake, Exhaust & Engine Gasket Sets

Engine Gaskets - Intake, Exhaust & Complete Gasket Sets High-quality gaskets for...

-

Forced Induction

Forced Induction - Turbocharger Parts & AccessoriesPremium forced induction components for turbocharged...

-

Proflow Intake Manifolds - LS Holden Ford

High-Performance Proflow Intake Manifolds for LS, Holden & Ford EnginesUnlock peak engine...

-

Fuel Injection, Throttle Body's & Fuel Rails

Fuel Injection, Throttle Bodies & Fuel Rails – Precise Fuel Delivery for...

-

Cooling Systems - Oil Coolers, Transmission Coolers & Water Pumps

High-Performance Cooling Systems - Oil Coolers, Transmission Coolers & Heat Management Keep...

-

Drivetrain Components - Transmission & Driveline Parts

High-Performance Drivetrain, Transmission & Driveline ComponentsPremium drivetrain parts for reliable power transfer...

-

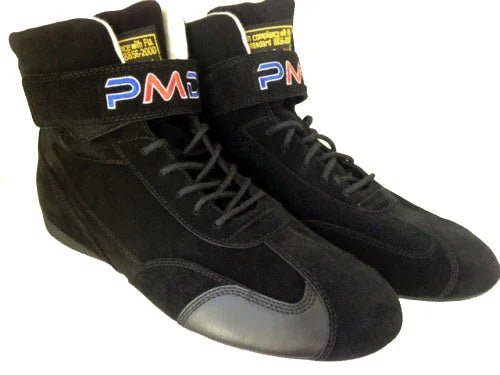

Race Suits / Apparel - Order in available!

Order in available! (We want to supply you with the newest dates...

-

Shocks & Springs

Fox bypass kit, Shaft, Bottom eyelet, King shocks rebuild kit, Fox mounting...

-

Silicone Hose, Bends and Reducers

Premium Silicone Hoses, Bends, Reducers & Brake Duct Hose SS Racetech stocks...

-

Steering & Shifters - Steering Columns & U-Joints

Steering & Shifters - Precision Control Components for Custom Builds Upgrade your...

-

Bearings & Seals

This collection offers Timken bearings, set 38, and oil seals. Find tapered...

-

Lubricants & Chemicals

Shop top-quality multi-purpose lubricant for cars and other high-performance automotive chemicals. Keep...

-

Electrical Components - Ignition, Alternators & Wiring

High-Performance Electrical Components - Ignition Systems, Alternators & Wiring Upgrade your vehicle's...

-

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds...

-

Custom Engines - Engine Rebuilds & Performance Builds

Custom Engine Builds - Rebuilds, Performance Upgrades & Complete Engines Unlock your...

-

Metric & Imperial Fasteners

SS Racetech Rods & Customs is your trusted source for...

-

Tyres & Wheels

Performance Tyres & Wheels for Race Cars & Street Machines High-performance tyres...

-

Drives & Pulleys - Performance Pulleys & Belt Tensioners

Drives & Pulleys - Performance Pulleys & Belt Tensioners Optimize your engine's...