Collection: Speedflow Hose - Braided Stainless Hose for Fuel, Oil & Brake

Premium Speedflow Braided Hose - Fuel, Oil, Coolant & Brake Lines

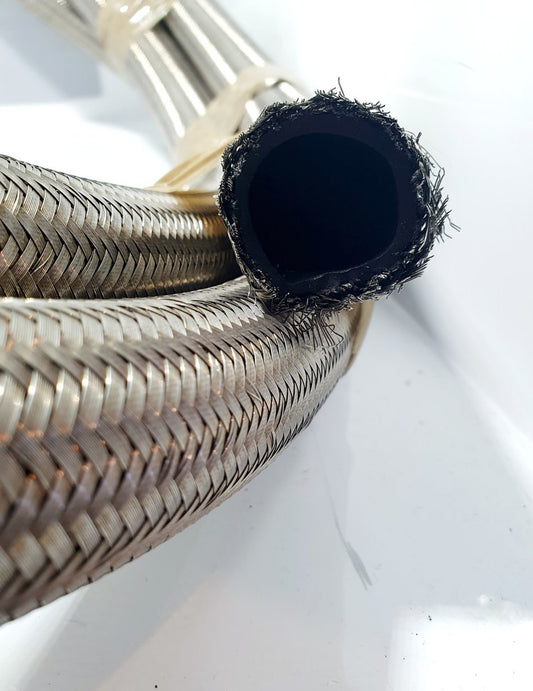

Complete range of Speedflow braided stainless steel hose for high-performance plumbing systems in Australian race cars, street machines, and custom builds. Available in 100, 200, and 400 Series to match your specific application and fitting type, from -3AN to -20AN sizes. Now including blackened hose for stealth appearance.

Shop Speedflow Hose by Series

Choose the right hose series to match your fittings and application:

100 Series Braided Hose

- Browse 100 Series Hose - For use with 100 Series reusable screw-together fittings

- ✅ Compatible with 100 Series reusable hose ends

- ✅ PTFE inner liner for fuel, oil, and brake applications

- ✅ Professional-grade construction for maximum reliability

- ✅ Reusable fittings can be disassembled and reassembled

200 Series Braided Hose

- Browse 200 Series Hose - For use with 200 Series push-on barbed fittings

- ✅ Compatible with 200 Series push-on barbed hose ends

- ✅ Works with steel and aluminium fittings

- ✅ Excellent vibration resistance for race applications

- ✅ PTFE liner resists fuel degradation

- ✅ Available in standard stainless and black finish

200 Series Blackened Braided Hose

- Browse 200 Series Black Hose - Blackened stainless steel for stealth appearance

- ✅ Black PVC coating over stainless steel braid

- ✅ Same performance as standard 200 Series hose

- ✅ Perfect for show cars and clean engine bay presentation

- ✅ Hides dirt and maintains appearance longer

400 Series Braided Hose

- Browse 400 Series Hose - For use with 400 Series push-lock fittings

- ✅ Compatible with 400 Series push-lock hose ends

- ✅ Easiest to assemble - no special tools required

- ✅ Full-flow design for maximum performance

- ✅ Perfect for quick installations and field repairs

Complete Your Plumbing System

Hose Ends & Fittings:

- 100 Series Hose Ends - Reusable screw-together fittings in all angles

- 200 Series Hose Ends - Push-on barbed fittings for permanent installations

- 400 Series Hose Ends - Push-lock fittings (straight, 30°, 45°, 60°, 90°, 120°, 150°, 180°)

- Browse all Speedflow fittings - Adapters, unions, bulkheads, and specialty fittings

Installation Guides:

- 100 Series Installation Guide - Step-by-step assembly instructions

- 200 Series Installation Guide - Push-on fitting installation

- 400 Series Installation Guide - Push-lock assembly guide

Related Systems:

- Fuel system components - Pumps, regulators, filters, and fuel line kits

- Oil system components - Oil coolers, filters, and accessories

- Cooling system parts - Oil coolers, water pumps, and hoses

- Brake components - Brake lines, fittings, and hardware

Australian Stock - Perth Dispatch

-

Blackened Teflon hose -3 per meter (SFT200-03-BLK)

Vendor:SS Racetech Rods & CustomsRegular price $70.75 AUDRegular price -

Blackened Teflon hose -4 per meter (SFT200-04-BLK)

Vendor:SS Racetech Rods & CustomsRegular price $74.85 AUDRegular price -

Blackened Teflon hose -8 per meter (SFT200-08-BLK)

Vendor:SS Racetech Rods & CustomsRegular price $118.70 AUDRegular price -

Currently Unavailable

Currently UnavailableBlackened Teflon hose -6 per meter ( SFT200-06-BLK )

Vendor:SS Racetech Rods & CustomsRegular price $91.40 AUDRegular price -

Blackened Teflon hose -10 per meter (SFT200-10-BLK)

Vendor:SS Racetech Rods & CustomsRegular price $125.55 AUDRegular price -

Blackened Teflon hose -12 per meter (SFT200-12-BLK)

Vendor:SS Racetech Rods & CustomsRegular price $185.80 AUDRegular price -

High performance hose -4 per meter (SFG100-04 )

Vendor:SS Racetech Rods & CustomsRegular price $60.00 AUDRegular price -

High performance hose -6 per meter (SFG100-06)

Vendor:SS Racetech Rods & CustomsRegular price $69.30 AUDRegular price -

High performance hose -8 per meter (SFG100-08)

Vendor:SS Racetech Rods & CustomsRegular price $72.05 AUDRegular price -

High performance hose -10 per meter (SFG100-10)

Vendor:SS Racetech Rods & CustomsRegular price $121.55 AUDRegular price -

High performance hose -12 per meter (SFG100-12)

Vendor:SS Racetech Rods & CustomsRegular price $133.40 AUDRegular price -

High performance hose -16 per meter (SFG100-16)

Vendor:SS Racetech Rods & CustomsRegular price $194.60 AUDRegular price -

High performance hose -20 per meter (SFG100-20)

Vendor:SS Racetech Rods & CustomsRegular price $281.10 AUDRegular price -

Teflon hose stainless steel braided -3 per meter (SFT200-03)

Vendor:SS Racetech Rods & CustomsRegular price $36.95 AUDRegular price -

Teflon hose stainless steel braided -4 per meter (SFT200-04)

Vendor:SS Racetech Rods & CustomsRegular price $41.10 AUDRegular price -

Teflon hose stainless steel braided - 6 per meter (SFT200-06)

Vendor:SS Racetech Rods & CustomsRegular price $62.45 AUDRegular price -

Teflon hose stainless steel braided -8 per meter (SFT200-08)

Vendor:SS Racetech Rods & CustomsRegular price $98.65 AUDRegular price -

Teflon hose stainless steel braided -10 per meter (SFT200-10)

Vendor:SS Racetech Rods & CustomsRegular price $121.65 AUDRegular price -

Teflon hose stainless steel braided -12 per meter (SFT200-12)

Vendor:SS Racetech Rods & CustomsRegular price $151.95 AUDRegular price -

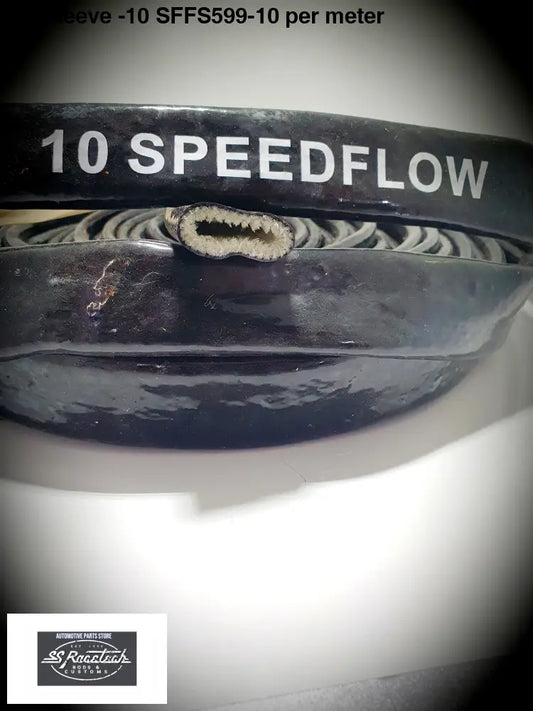

Speedflow Firesleeve Heat Sleeve Black -4 AN Braided Fibreglass Silicone Coated Per Meter - SFFS599-04

Vendor:SS Racetech Rods & CustomsRegular price $23.30 AUDRegular price -

Speedflow Firesleeve Heat Sleeve Black -6 AN Braided Fibreglass Silicone Coated Per Meter - SFFS599-06

Vendor:SS Racetech Rods & CustomsRegular price $36.30 AUDRegular price -

Speedflow Firesleeve Heat Sleeve Black -8 AN Braided Fibreglass Silicone Coated Per Meter - SFFS599-08

Vendor:SS Racetech Rods & CustomsRegular price $42.15 AUDRegular price -

Speedflow Firesleeve Heat Sleeve Black -10 AN Braided Fibreglass Silicone Coated Per Meter - SFFS599-10

Vendor:SS Racetech Rods & CustomsRegular price $52.75 AUDRegular price -

Speedflow Firesleeve Heat Sleeve Black -12 AN Braided Fibreglass Silicone Coated Per Meter - SFFS599-12

Vendor:SS Racetech Rods & CustomsRegular price $65.10 AUDRegular price

Have a question?

Speedflow Hose FAQ

What types of fluids are Speedflow hoses compatible with?

Speedflow hoses are engineered for broad compatibility across fuel, oil, and coolant systems, making them ideal for a range of automotive builds—from high-horsepower race cars to street machines and custom projects. Whether you’re routing E85, gasoline, transmission fluid, or coolant, Speedflow hoses ensure reliable, leak-free performance and help prevent contamination or system failure thanks to their specialized, high-quality materials.

How do I choose the right Speedflow hose for my project?

Choosing the right hose comes down to your application, desired pressure rating, and fluid type. For most street and race fuel or oil setups, the 100 Series and 200 Series hoses are go-to options—offering reinforced construction and flexibility. If you require high chemical resistance (like for brake fluid or E85), the 200 Series Teflon Blackened Stainless Steel Braided Hose is a great pick. Need easy installation on push-on barbs? The Pushlock Hose gives you a secure fit without extra clamps. Not sure what you need? Check your system's pressure and fluid compatibility, or reach out to our team for expert recommendations.

Are Speedflow hoses easy to install for DIY automotive builds?

Absolutely! Speedflow hoses are designed with the enthusiast in mind, featuring user-friendly installation and a variety of compatible hose ends (sold separately) to ensure leak-free connections. The precision braiding and flexibility mean you can route the hoses in tight engine bays or custom setups without kinking or collapsing. For best results, use appropriate hose cutters, lube the fittings, and follow our install guides. Don’t forget to use hose separators and clamps for tidy, vibration-free routing.

How durable and long-lasting are Speedflow hoses?

Speedflow hoses are built using high-quality materials—like premium stainless steel braiding and Teflon inner linings—making them exceptionally durable even in harsh, high-pressure, and high-temperature automotive environments. Their corrosion-resistant properties ensure long-term reliability, whether exposed to fuel, oil, or coolant. With proper installation and routine inspection, most users enjoy years of trouble-free service from their Speedflow hoses, both on the track and the street.

What maintenance is required to keep Speedflow hoses in top condition?

Maintaining your Speedflow hoses is straightforward: periodically inspect for signs of wear, cracking, or leaks—especially around fittings and areas exposed to heat. Clean external surfaces with a mild detergent to remove grime and prevent buildup. If your hoses are routed near extreme heat sources, consider adding a Firesleeve for extra protection. Always replace hoses at the recommended service interval, or sooner if you notice any damage, to stay race-ready and road-safe.

-

Air Filters - High-Flow Performance & Reusable Filters

High-Performance Air Filters - Washable, Reusable & High-Flow Maximize engine performance and...

-

Alternators & Accessories - High-Output Alternators & Brackets

Alternators & Accessories - High-Output Alternators & Mounting Brackets Upgrade your vehicle's...

-

Speedflow Hose - Braided Stainless Hose for Fuel, Oil & Brake

Premium Speedflow Braided Hose - Fuel, Oil, Coolant & Brake Lines Complete...

-

Speedflow Fittings

Premium Speedflow AN Fittings, Hose Ends & Adapters for High-Performance Plumbing Complete...

-

Engine Accessories - Performance Parts & Upgrades

Premium Engine Accessories - Performance Parts for Custom Builds & Motorsport Upgrade...

-

Fabrication Parts - Exhaust, Mandrel Bends & Weld Fittings

Premium Fabrication Parts - Custom Exhaust, Intake & Chassis Components Complete your...

-

ARP Fasteners - Head Studs, Main Studs & Rod Bolts

ARP Fasteners - Premium Head Studs, Main Studs & Engine Bolts Build...

-

Fuel Systems - Fuel Pumps, Regulators & AN Fittings

📋 Fuel System Plumbing Guide → Download our complete fuel system plumbing...

-

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps Upgrade...

-

Stainless Steel & Aluminium Bends and Tube

Premium Mandrel Bends & Tube for Custom Exhaust Fabrication Professional-grade stainless steel...

-

Racing Seats

Shop Proforce Safety racing seats at SS Racetech Rods & Customs. Experience...

-

Safety Equipment - Quick Release Latches & Bonnet Pins

Safety Equipment - Quick Release Latches, Bonnet Pins & Racing Safety Ensure...

-

Suspension - Uniball Bearings, Rod Ends & Bushings

Premium Suspension Components - Uniball Bearings, Rod Ends & Bushings Upgrade your...

-

Rod Ends & Uniballs - FK Heim Joints

Premium Rod Ends, Uniballs & Heim Joints for Steering & Suspension High-performance...

-

Carburetors & Accessories - Spacers, Studs & Fuel Line Kits

Carburetors & Accessories - Spacers, Mounting Hardware & Fuel Lines Optimize your...

-

Gaskets - Intake, Exhaust & Engine Gasket Sets

Engine Gaskets - Intake, Exhaust & Complete Gasket Sets High-quality gaskets for...

-

Forced Induction

Forced Induction - Turbocharger Parts & AccessoriesPremium forced induction components for turbocharged...

-

Proflow Intake Manifolds - LS Holden Ford

High-Performance Proflow Intake Manifolds for LS, Holden & Ford EnginesUnlock peak engine...

-

Fuel Injection, Throttle Body's & Fuel Rails

Fuel Injection, Throttle Bodies & Fuel Rails – Precise Fuel Delivery for...

-

Cooling Systems - Oil Coolers, Transmission Coolers & Water Pumps

High-Performance Cooling Systems - Oil Coolers, Transmission Coolers & Heat Management Keep...

-

Race Suits / Apparel - Order in available!

Order in available! (We want to supply you with the newest dates...

-

Shocks & Springs

Fox bypass kit, Shaft, Bottom eyelet, King shocks rebuild kit, Fox mounting...

-

Silicone Hose, Bends and Reducers

Premium Silicone Hoses, Bends, Reducers & Brake Duct Hose SS Racetech stocks...

-

Steering & Shifters - Steering Columns & U-Joints

Steering & Shifters - Precision Control Components for Custom Builds Upgrade your...

-

Bearings & Seals

This collection offers Timken bearings, set 38, and oil seals. Find tapered...

-

Lubricants & Chemicals

Shop top-quality multi-purpose lubricant for cars and other high-performance automotive chemicals. Keep...

-

Electrical Components - Ignition, Alternators & Wiring

High-Performance Electrical Components - Ignition Systems, Alternators & Wiring Upgrade your vehicle's...

-

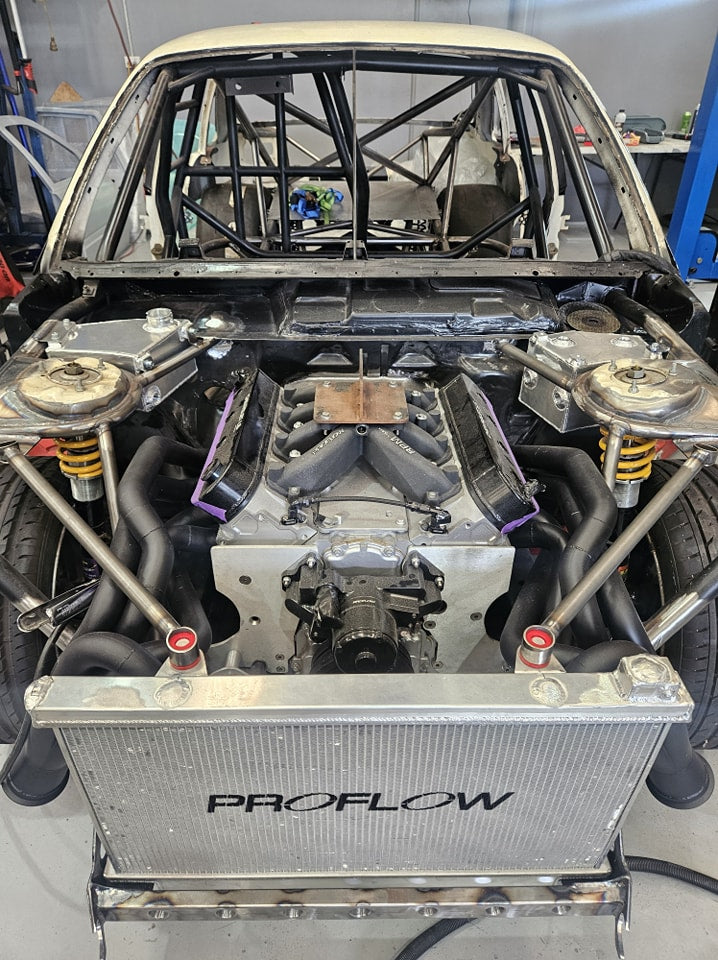

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds...

-

Custom Engines - Engine Rebuilds & Performance Builds

Custom Engine Builds - Rebuilds, Performance Upgrades & Complete Engines Unlock your...

-

Metric & Imperial Fasteners

SS Racetech Rods & Customs is your trusted source for...

-

Tyres & Wheels

Performance Tyres & Wheels for Race Cars & Street Machines High-performance tyres...

-

Drives & Pulleys - Performance Pulleys & Belt Tensioners

Drives & Pulleys - Performance Pulleys & Belt Tensioners Optimize your engine's...