-

Aeroflow Dual Stainless Steel Hard Line Clamps 5/16" & 3/8" 7.9mm 9.5mm OD 6 Pack - AF300-06-05

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $60.30 AUDRegular price -

Aeroflow Stainless Steel Hard Line Clamps 3/8" 9.5mm OD 12 Pack - AF300-01

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $64.10 AUDRegular price -

Billet Gas Pedal Kit with 24" Throttle Cable - Black Aluminium Hot Rod (05ITD001CBK)

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $98.00 AUDRegular price$60.00 AUDSale price $98.00 AUD -

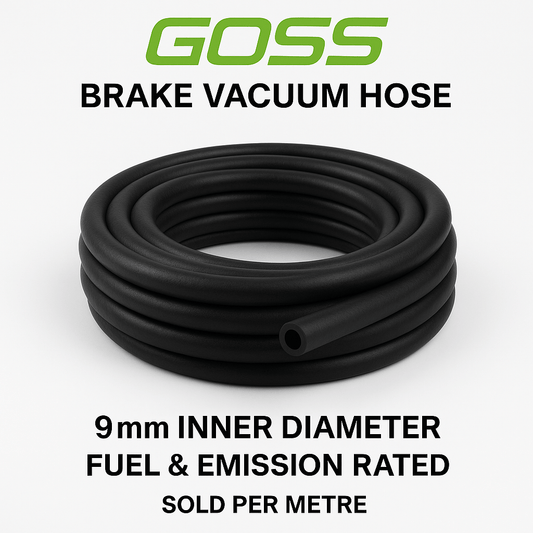

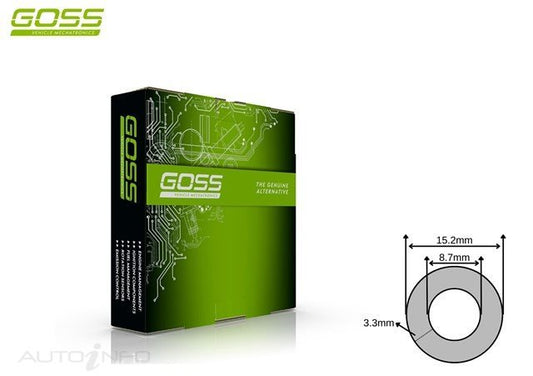

Brake Vacuum Hose 9mm ID x 1 metre Length

Vendor:SS Racetech Rods & CustomsRegular price $14.50 AUDRegular price -

CNC Blue 2 PSI Disc Brake Pressure Residual Valve Does Not Include Fittings

Vendor:SS Racetech Rods & CustomsRegular price $83.00 AUDRegular price -

Forch Brake cleaner premium R510 600ML

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $15.00 AUDRegular price -

HAWK BRAKE PADS TO SUIT 3/8 ROTOR - SET OF 4 HB102 BLK

Vendor:SS Racetech Rods & CustomsRegular price $738.00 AUDRegular price -

HWK-HB102G-600 Hawk Performance HB102G.600 DTC-60 High Temp Compound 6" Brake Pads 0.600" Thick - Set Of 4

Vendor:SS Racetech Rods & CustomsRegular price $525.40 AUDRegular price -

JAM-JCAL-200 Jamar Performance Driver Or Passenger Billet Aluminum 2 Piston Mini Disc Brake Caliper With Pads

Vendor:SS Racetech Rods & CustomsRegular price $314.20 AUDRegular price -

Currently Unavailable

Currently UnavailablePFE341-03 Proflow Stainless Brake Adaptor Male Inverted Flare -03AN to 7/16 x 24

Vendor:SS Racetech Rods & CustomsRegular price $19.50 AUDRegular price -

PFE341-04 Proflow Stainless Brake Adaptor Male Inverted Flare -04AN to 7/16 x 24

Vendor:SS Racetech Rods & CustomsRegular price $15.00 AUDRegular price -

PFE386 Proflow Billet Aluminium Brake Proportioning Valve, Knob Adjustment, 3/8in. x24, Single Inlet/Outlet, Each

Vendor:SS Racetech Rods & CustomsRegular price $67.70 AUDRegular price -

PFEADR300 Proflow Brake Line -03AN Stainless Hose End ADR 300mm

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $99.00 AUDRegular price -

PFEADR350 Proflow Brake Line -03AN Stainless Hose End ADR 350mm

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $107.65 AUDRegular price -

Currently Unavailable

Currently UnavailablePFEADR400 Proflow Brake Line -03AN Stainless Hose End ADR 400mm

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $111.60 AUDRegular price -

Currently Unavailable

Currently UnavailablePFEADR450 Proflow Brake Line -03AN Stainless Hose End ADR 450mm

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $112.00 AUDRegular price -

PFEADR550 Proflow Brake Line -03AN Stainless Hose End ADR 550mm

Vendor:SS Racetech Rods & CustomsRegular price $119.95 AUDRegular price -

Polished billet aluminium firewall mount accelerator pedal -LK-011

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $128.70 AUDRegular price -

Proflow ADR Approved Braided Brake Line - AN3 Stainless 250mm | PFEADR250

Vendor:SS Racetech Rods & CustomsRegular price $99.00 AUDRegular price -

Proflow ADR Brake Line -03AN Stainless Braided 500mm - Street Legal (PFEADR500)

Vendor:SS Racetech Rods & CustomsRegular price $116.40 AUDRegular price -

Proflow Silicone Brake Duct Hose 2.0" Black 2m Length - 51mm ID (PFESBD051-2)

Vendor:SS Racetech Rods & CustomsRegular price $84.35 AUDRegular price -

Currently Unavailable

Currently UnavailableProflow Silicone Brake Duct Hose 2.5" Black 2m Length - 63mm ID (PFESBD063-2)

Vendor:SS Racetech Rods & CustomsRegular price $70.90 AUDRegular price -

Proflow Silicone Brake Duct Hose 3.0" Black 2m Length - 76mm ID (PFESBD076-2)

Vendor:SS Racetech Rods & CustomsRegular price $86.60 AUDRegular price -

Proflow Silicone Brake Duct Hose 3.5" 89mm ID x 2 Metre Black - Heat Resistant - PFESBD089-2

Vendor:SS Racetech Rods & CustomsRegular price $100.35 AUDRegular price

Collection: Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps

Upgrade your vehicle's braking system with our comprehensive range of brake components designed for Australian race cars, street machines, and custom builds. From braided stainless brake lines and AN fittings to hardline clamps and pedal assemblies, we stock everything you need for reliable, high-performance braking.

Brake Lines & Hoses

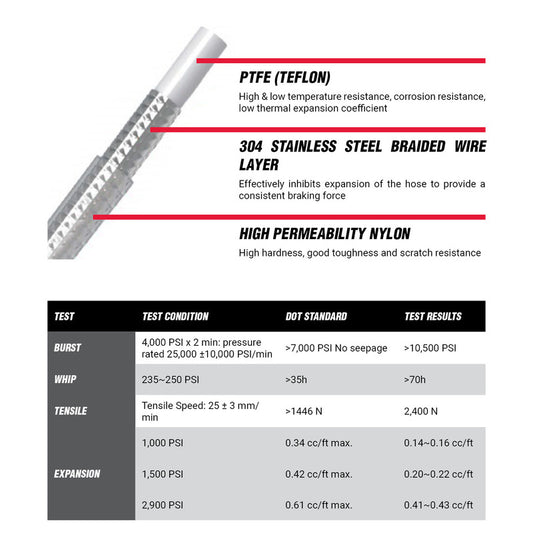

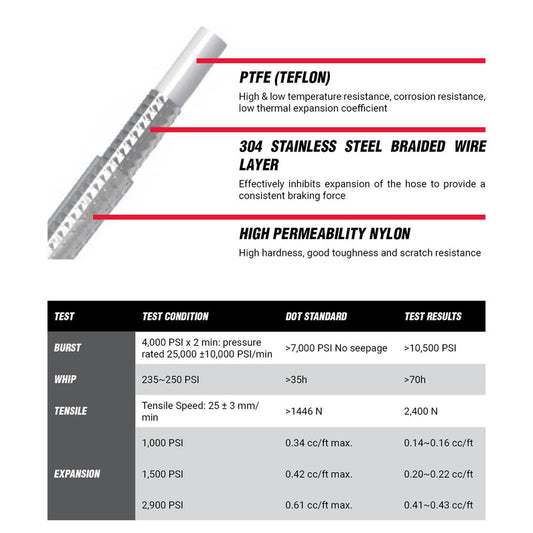

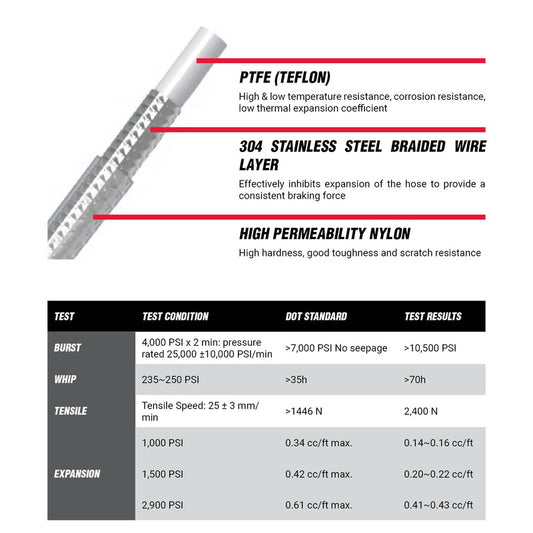

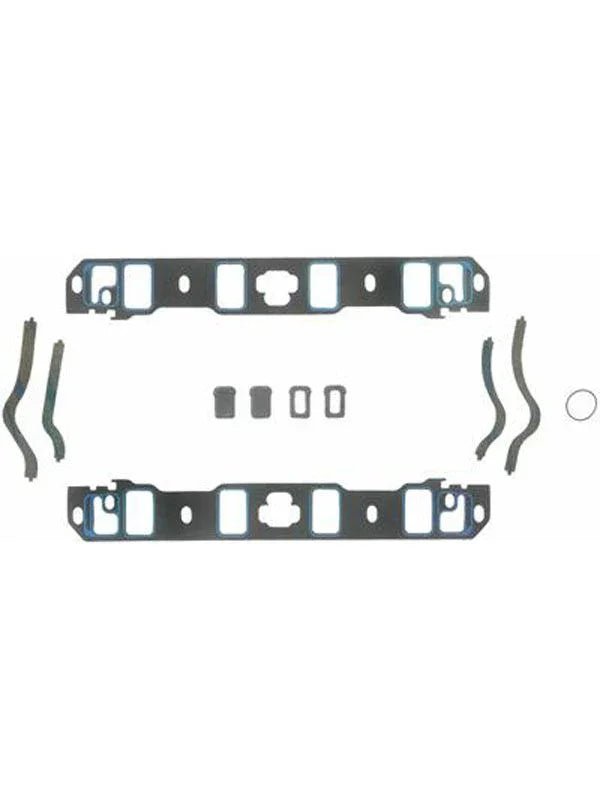

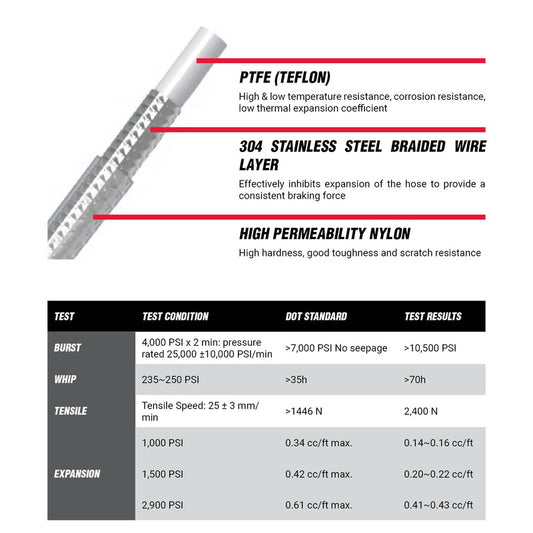

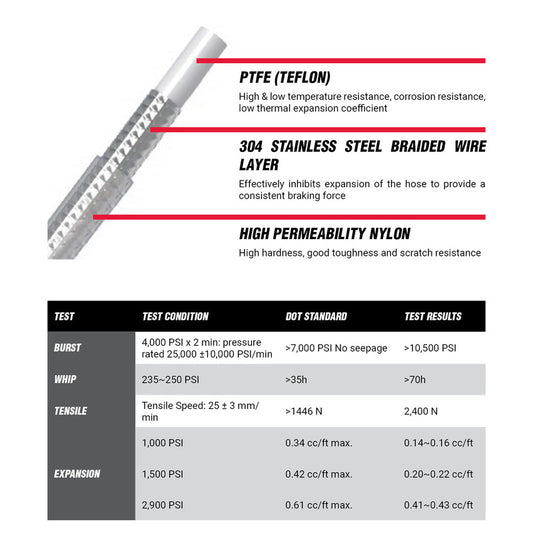

- Braided Stainless Brake Lines: PTFE-lined stainless steel braided hose in -3AN size for firm pedal feel and consistent brake pressure

- DOT-Approved Brake Hose: Street-legal braided brake lines meeting ADR and DOT specifications

- Custom Brake Line Kits: Pre-made brake line sets for popular applications with correct fittings and lengths

- Brake Line Adapters: AN to metric and imperial adapters for brake caliper connections

Brake Line Fittings & Hardware

- AN Brake Hose Ends: -3AN stainless steel hose ends in straight, 30°, 45°, 90°, and 180° configurations for custom brake line routing

- Banjo Fittings: Banjo bolts and banjo adapters for brake caliper connections

- Brake Line Unions: Inline unions and tee fittings for brake line junctions and distribution

- Hardline Clamps: Stainless steel and aluminium clamps to secure steel brake lines to chassis and body

- Brake Line Clips: P-clips and mounting brackets for professional brake line installation

Brake Pedal Assemblies & Components

- Brake Pedal Assemblies: Floor-mount and hanging pedal assemblies for custom chassis and race cars

- Balance Bar Assemblies: Adjustable brake bias bars for dual master cylinder setups

- Pedal Pads: Rubber and billet aluminium brake pedal pads for improved grip

- Clevis Pins & Hardware: Mounting hardware for pedal connections

Why Upgrade Brake Components?

Factory rubber brake lines expand under pressure, creating spongy pedal feel and inconsistent braking. Braided stainless steel brake lines eliminate expansion for firm, consistent pedal feel and improved brake modulation. AN fittings provide leak-free connections that won't fail under high brake pressure. Proper hardline clamps prevent brake line vibration and chafing that causes leaks and failures. Upgrading brake components improves safety, performance, and reliability in street and race applications.

Brake Line Selection Guide

Brake Line Size: -3AN (3/16" ID) is standard for most automotive brake applications. Provides adequate flow for single and dual-piston calipers. -4AN used for large multi-piston calipers or long brake line runs. Never use smaller than -3AN for brake lines.

PTFE vs Rubber Inner Line: PTFE (Teflon) lined brake hose is mandatory for performance applications. PTFE doesn't expand under pressure and resists brake fluid degradation. Standard rubber inner hose expands and deteriorates—not suitable for performance braking.

DOT Compliance: Street-driven vehicles require DOT-approved brake lines meeting FMVSS 106 standards. Race-only vehicles can use non-DOT lines. Check local regulations for compliance requirements.

Common Brake System Applications

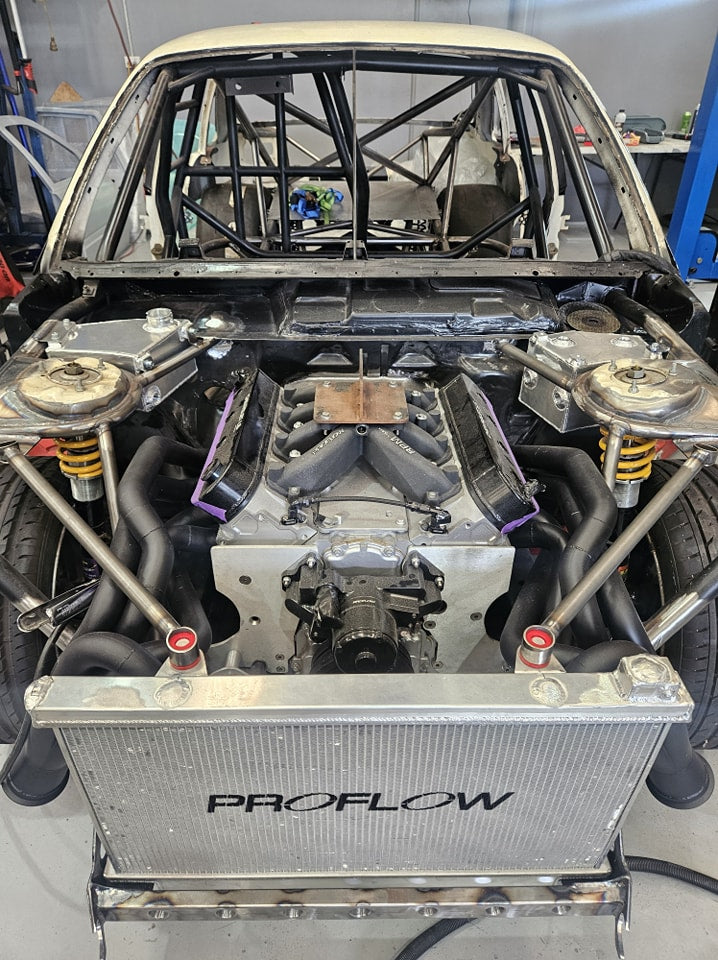

- Custom brake line installations for engine swaps

- Race car brake systems with upgraded brake lines

- Brake upgrades with larger calipers requiring new lines

- Classic car brake line replacement and upgrades

- Custom chassis builds with floor-mount pedal assemblies

- Brake bias adjustment for circuit racing and drifting

- Show car builds with polished and braided brake lines

Related Performance Components

Complete your brake system with complementary components:

- Speedflow AN Fittings: Complete range of AN hose ends and adapters for brake line plumbing

- Speedflow Braided Hose: PTFE-lined stainless steel hose for brake, fuel, and oil systems

- Steering & Shifters: Pedal assemblies and mounting components

- Fabrication Parts: Steel tube and brackets for custom pedal box fabrication

Installation & Safety Tips

Brake Line Routing: Route brake lines away from exhaust heat, sharp edges, and moving components. Use proper clamps every 300-400mm to prevent vibration and chafing. Ensure adequate slack for suspension travel—lines must not pull tight at full droop or compression.

Fitting Installation: Use proper AN wrenches to avoid damaging fittings. Torque fittings to specification—over-tightening damages threads and seals. Apply brake fluid to threads before assembly for proper torque reading and corrosion prevention.

Bleeding Procedure: Always bleed brake system after installing new lines. Start with wheel furthest from master cylinder and work toward closest. Use fresh DOT 3, DOT 4, or DOT 5.1 fluid (never mix DOT 5 silicone fluid with glycol-based fluids). Bleed until no air bubbles appear.

Pressure Testing: Pressure test brake system to 1000 PSI before driving. Check all fittings and connections for leaks. Pump brake pedal firmly 20-30 times and verify firm pedal feel. Never drive vehicle with soft or spongy brake pedal.

Performance Benefits

- Firm, consistent brake pedal feel without sponginess

- Improved brake modulation and control

- Leak-free connections with AN fittings

- Resistance to brake fluid degradation and heat

- Professional appearance with braided stainless lines

- Reliable performance in street and race applications

- Secure brake line mounting with hardline clamps

Fast Shipping Across Australia - Same-day dispatch on orders placed before 2 PM AWST.

-

Air Filters - High-Flow Performance & Reusable Filters

High-Performance Air Filters - Washable, Reusable & High-FlowMaximize engine performance and efficiency...

-

Alternators & Accessories - High-Output Alternators & Brackets

Alternators & Accessories - High-Output Alternators & Mounting Brackets Upgrade your vehicle's...

-

Speedflow Hose - Braided Stainless Hose for Fuel, Oil & Brake

Premium Speedflow Braided Hose - Fuel, Oil, Coolant & Brake Lines Complete...

-

Speedflow Fittings - AN Fittings Hose Ends Adapters

Premium Speedflow AN Fittings, Hose Ends & Adapters for High-Performance Plumbing Complete...

-

Engine Accessories - Performance Parts & Upgrades

Premium Engine Accessories - Performance Parts for Custom Builds & Motorsport Upgrade...

-

Fabrication Parts - Exhaust, Mandrel Bends & Weld Fittings

Premium Fabrication Parts - Custom Exhaust, Intake & Chassis ComponentsComplete your custom...

-

🚨 On Sale & Clearance stock 🚨

Current Package deals at SS Racetech Rods & Customs🔥click here! Shop SS...

-

SS Racetech New Arrivals Featuring Holley Carburetor Parts

Explore the newest arrivals at SS Racetech featuring Holley small parts...

-

ARP Fasteners - Head Studs, Main Studs & Rod Bolts

ARP Fasteners - Premium Head Studs, Main Studs & Engine Bolts Build...

-

Fuel Systems - Fuel Pumps, Regulators & AN Fittings

📋 Fuel System Plumbing Guide → Download our complete fuel system plumbing...

-

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps Upgrade...

-

Stainless Steel & Aluminium Bends and Tube

Premium Mandrel Bends & Tube for Custom Exhaust FabricationProfessional-grade stainless steel and...

-

Racing Seats

Shop Proforce Safety racing seats at SS Racetech Rods & Customs. Experience...

-

Safety Equipment - Quick Release Latches & Bonnet Pins

Safety Equipment - Quick Release Latches, Bonnet Pins & Racing Safety Ensure...

-

Suspension - Uniball Bearings, Rod Ends & Bushings

Premium Suspension Components - Uniball Bearings, Rod Ends & Bushings Upgrade your...

-

Rod Ends & Uniballs - FK Heim Joints

Premium Rod Ends, Uniballs & Heim Joints for Steering & Suspension High-performance...

-

Carburetors & Accessories - Spacers, Studs & Fuel Line Kits

Carburetors & Accessories - Spacers, Mounting Hardware & Fuel Lines Optimize your...

-

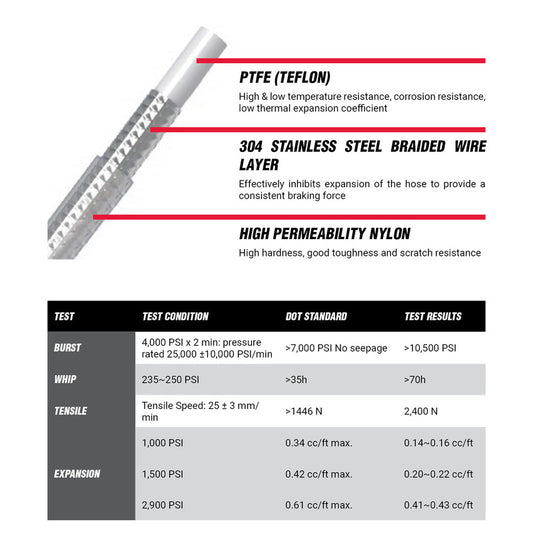

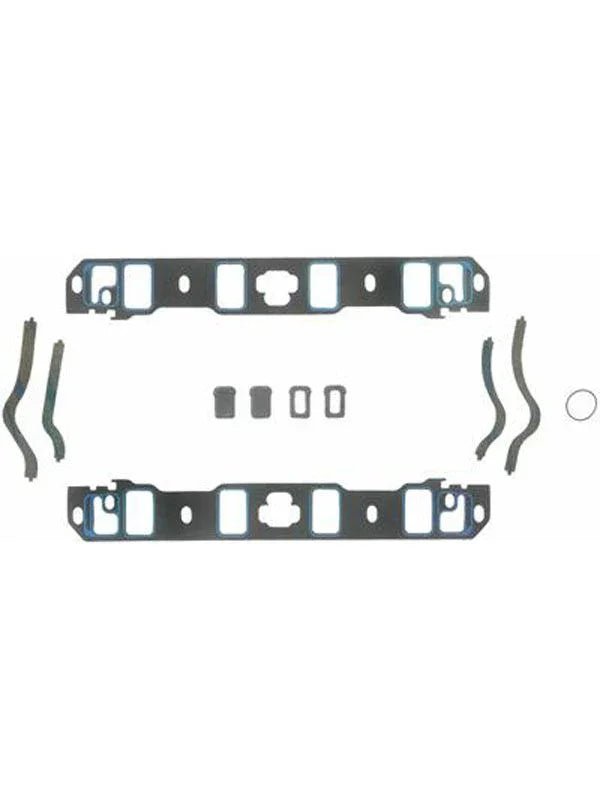

Gaskets - Intake, Exhaust & Engine Gasket Sets

Premium Engine Gaskets - Intake, Exhaust & Complete Gasket Sets Ensure leak-free...

-

Forced Induction

Explore the Forced Induction collection at SS Racetech Rods & Customs. Find...

-

Proflow Intake Manifolds - LS Holden Ford

High-Performance Proflow Intake Manifolds for LS, Holden & Ford EnginesUnlock peak engine...

-

Fuel Injection, Throttle Body's & Fuel Rails

Fuel Injection, Throttle Bodies & Fuel Rails – Precise Fuel Delivery for...

-

Cooling Systems - Oil Coolers, Transmission Coolers & Water Pumps

High-Performance Cooling Systems - Oil Coolers, Transmission Coolers & Heat Management Keep...

-

Drivetrain Components - Transmission & Driveline Parts

High-Performance Drivetrain, Transmission & Driveline Components Premium drivetrain parts for reliable power...

-

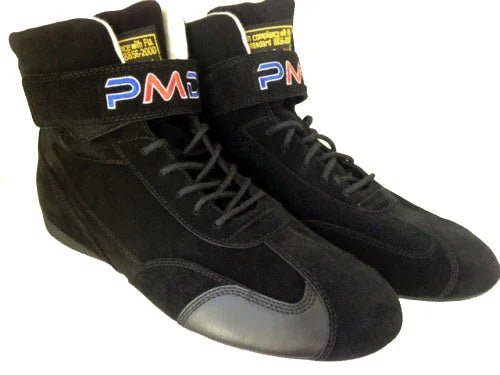

Race Suits / Apparel - Order in available!

Order in available! (We want to supply you with the newest dates...

-

Shocks & Springs

Fox bypass kit, Shaft, Bottom eyelet, King shocks rebuild kit, Fox mounting...

-

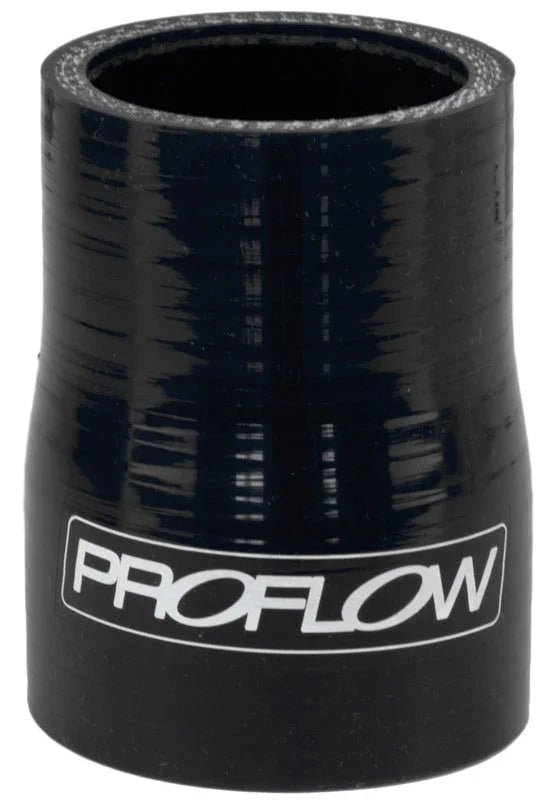

Silicone Hose, Bends and Reducers

Premium Silicone Hoses, Bends, Reducers & Brake Duct Hose SS Racetech stocks...

-

Steering & Shifters - Steering Columns & U-Joints

Steering & Shifters - Precision Control Components for Custom Builds Upgrade your...

-

Bearings & Seals

This collection offers Timken bearings, set 38, and oil seals. Find tapered...

-

Lubricants & Chemicals

Shop top-quality multi-purpose lubricant for cars and other high-performance automotive chemicals. Keep...

-

Electrical Components - Ignition, Alternators & Wiring

High-Performance Electrical Components - Ignition Systems, Alternators & Wiring Upgrade your vehicle's...

-

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds...

-

Custom Engines - Engine Rebuilds & Performance Builds

Custom Engine Builds - Rebuilds, Performance Upgrades & Complete Engines Unlock your...

-

Metric & Imperial Fasteners

SS Racetech Rods & Customs is your trusted source for...

-

Tyres & Wheels

Performance Tyres & Wheels for Race Cars & Street Machines High-performance tyres...

-

Drives & Pulleys - Performance Pulleys & Belt Tensioners

Drives & Pulleys - Performance Pulleys & Belt Tensioners Optimize your engine's...