-

Aeroflow Gilmer Drive Kit Black Ford Windsor Cleveland 289 302 351 Timing Belt Included - AF64-3002BLK

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $280.00 AUDRegular price -

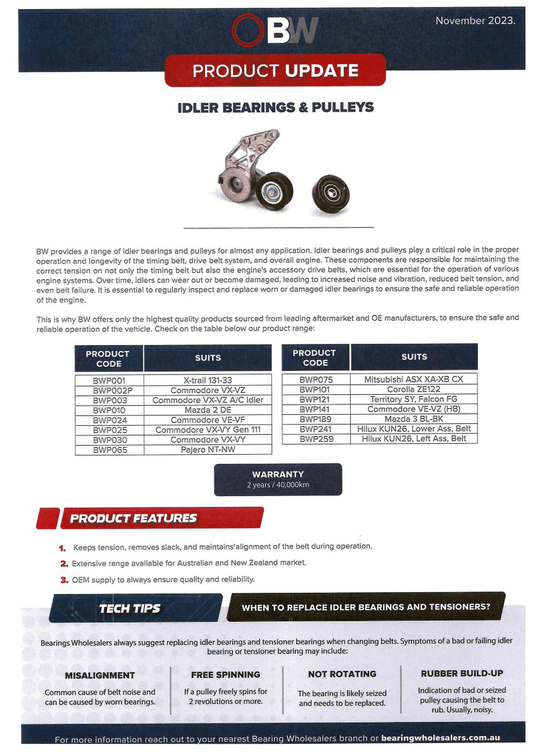

BW Drive Belt Tensioner Pulley - BWP240

Vendor:SS Racetech Rods & CustomsRegular price $21.30 AUDRegular price -

Currently Unavailable

Currently UnavailablePFEGK7170BK Proflow Alternator Pulley, Gilmer, 17mm bore, Bolt-On, Steel, Black, Each

Vendor:SS Racetech Rods & CustomsRegular price $86.70 AUDRegular price -

PFEP8855BK Proflow Pulley, V-Belt Crankshaft SB Chev Long Water Pump 1-Groove, Black Aluminium

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $114.65 AUDRegular price -

PFETT100LSBK Proflow Belt Tensioner, For Holden Commodore LS VT-VZ, Billet Aluminium, Black Anodised

Vendor:SS Racetech Rods & CustomsRegular price $229.15 AUDRegular price -

Proflow Billet Aluminium Belt Drive Pulley Kit - SB Chev Long Water Pump PFEGK80252

Vendor:SS Racetech Rods & CustomsRegular price $272.10 AUDRegular price -

Proflow Billet Gilmer Drive Belt Kit - Chevrolet SBC Short Water Pump Black | PFEGK80251BK

Vendor:SS Racetech Rods & CustomsRegular price $284.00 AUDRegular price -

Proflow Billet Gilmer Drive Belt Kit - Ford Cleveland 302/351 Black | PFEGK80255BK

Vendor:SS Racetech Rods & CustomsRegular price $272.85 AUDRegular price -

Proflow Billet Gilmer Drive Belt Kit - Ford Cleveland 302/351 Silver | PFEGK80255

Vendor:SS Racetech Rods & CustomsRegular price $272.85 AUDRegular price -

Proflow Billet Gilmer Drive Belt Kit - Ford Windsor 289/302/351W Black | PFEGK80254BK

Vendor:SS Racetech Rods & CustomsRegular price $272.85 AUDRegular price -

Currently Unavailable

Currently UnavailableProflow Billet Gilmer Drive Belt Kit - Holden 253/308 Commodore V8 Black | PFEGK80258BK

Vendor:SS Racetech Rods & CustomsRegular price $269.00 AUDRegular price -

Proflow LS Belt Tensioner Billet Aluminium Black - Holden Commodore VE-VF (PFETT101LSBK)

Vendor:SS Racetech Rods & CustomsRegular price $234.10 AUDRegular price

Collection: Drives & Pulleys - Performance Pulleys & Belt Tensioners

Drives & Pulleys - Performance Pulleys & Belt Tensioners

Optimize your engine's accessory drive system with our range of performance pulleys and belt tensioners designed for Australian V8 conversions, street machines, and custom builds. From lightweight aluminium pulleys to adjustable tensioners and Gilmer drive systems, we stock everything you need for reliable power transfer and reduced parasitic drag.

Performance Pulleys

- Crankshaft Pulleys: Lightweight aluminium crank pulleys to reduce rotating mass and improve throttle response

- Alternator Pulleys: Overdrive and underdrive pulleys to optimize alternator speed and charging output

- Water Pump Pulleys: Performance pulleys for increased or decreased water pump speed depending on application

- Power Steering Pulleys: Optimized pulleys for proper power steering pump speed and pressure

- A/C Compressor Pulleys: Replacement pulleys for air conditioning compressor drives

- Idler Pulleys: Smooth-bearing idler pulleys for belt routing and tensioning

Belt Tensioners & Adjusters

- Automatic Belt Tensioners: Spring-loaded tensioners that maintain constant belt tension for drive systems

- Manual Belt Tensioners: Adjustable tensioners for custom belt routing and V-belt applications

- Tensioner Pulleys: Replacement pulley assemblies for worn tensioner bearings

- Belt Tension Gauges: Measurement tools for proper belt tension adjustment

Gilmer Drive Systems

- Gilmer Drive Kits: Toothed belt drive systems for positive engagement without slippage in racing applications

- Gilmer Pulleys: Toothed pulleys for crankshaft, camshaft, and accessory drives

- Gilmer Belts: High-strength toothed belts in various widths and tooth counts

- Gilmer Tensioners: Adjustable tensioners for toothed belt systems

V-Belt Drives & Components

- V-Belt Pulleys: Single and double-groove pulleys for traditional V-belt drive systems

- V-Belts: Standard and high-performance V-belts in various lengths

- V-Belt Tensioners: Adjustable mounting brackets for proper V-belt tension

Why Upgrade Your Drive System?

Factory drive systems use heavy steel pulleys and basic tensioners designed for cost and longevity, not performance. Lightweight aluminium pulleys reduce rotating mass on the crankshaft, improving throttle response and freeing up horsepower (typically 5-10hp on V8 engines). Underdrive pulleys slow accessory speeds to reduce parasitic drag, while overdrive pulleys increase alternator output for high-electrical-load applications. Performance pulleys and tensioners provide reliable power transfer and cleaner engine bay appearance.

Drive System Selection Guide

Underdrive vs Overdrive Pulleys: Underdrive pulleys slow accessories 15-25% to reduce parasitic drag and free up horsepower. Best for racing and performance street cars. Overdrive pulleys speed up alternator for increased charging output in vehicles with high electrical loads (electric fans, fuel pumps, audio systems).

Pulley Material: Aluminium pulleys are lightweight and reduce rotating mass but may not be suitable for supercharger or high-load applications. Steel pulleys are heavier but provide maximum strength for forced induction and extreme applications.

Gilmer vs V-Belt: Gilmer (toothed belt) systems provide positive engagement without slippage, ideal for racing and high-RPM applications. V-belt systems are traditional and work well for street rods and classic builds requiring period-correct appearance.

Common Drive System Applications

- V8 engine builds requiring performance pulleys

- Hot rod builds with traditional V-belt systems

- Race engines with lightweight pulley upgrades

- High-output alternator installations requiring overdrive pulleys

- Supercharger and ProCharger drive systems

- Custom engine builds with non-standard accessory layouts

- Gilmer drive conversions for racing applications

Related Engine Components

Complete your drive system upgrade with complementary components:

- Alternators: High-output alternators for increased electrical capacity

- Water Pumps: High-flow water pumps for improved cooling efficiency

- Engine Accessories: Complete range of performance engine components

- Fabrication Parts: Custom brackets and mounting hardware

Drive System Installation Tips

Belt Routing: Plan belt routing to ensure proper wrap on all pulleys (minimum 90° wrap on alternator and power steering). Use idler pulleys to achieve correct routing and belt tension. Verify belt clears all engine components and chassis.

Belt Tension: Belts should deflect 6-12mm with moderate thumb pressure at longest span. Over-tensioning causes bearing failure, under-tensioning causes slippage and noise. Use belt tension gauge for accurate adjustment.

Pulley Alignment: All pulleys must be aligned within 1-2mm to prevent belt wear and noise. Use straight edge across pulley faces to verify alignment. Shim brackets as needed for proper alignment.

Torque Specifications: Torque crankshaft pulley bolts to manufacturer specifications (typically 50-75 ft-lbs for aluminium pulleys). Use thread locker on all accessory mounting bolts. Safety-wire critical fasteners in race applications.

Performance Benefits

- Reduced rotating mass improves throttle response and acceleration

- Underdrive pulleys free up 5-15 horsepower by reducing parasitic drag

- Automatic tensioners maintain constant belt tension

- Lightweight aluminium construction reduces engine weight

- Improved belt wrap and routing reduces slippage

- Gilmer drives eliminate belt slippage in racing applications

- Clean, professional appearance in engine bay

Australian Stock

Fast Shipping Across Australia - Same-day dispatch on orders placed before 2 PM AWST.

-

Air Filters - High-Flow Performance & Reusable Filters

High-Performance Air Filters - Washable, Reusable & High-FlowMaximize engine performance and efficiency...

-

Alternators & Accessories - High-Output Alternators & Brackets

Alternators & Accessories - High-Output Alternators & Mounting Brackets Upgrade your vehicle's...

-

Speedflow Hose - Braided Stainless Hose for Fuel, Oil & Brake

Premium Speedflow Braided Hose - Fuel, Oil, Coolant & Brake Lines Complete...

-

Speedflow Fittings - AN Fittings Hose Ends Adapters

Premium Speedflow AN Fittings, Hose Ends & Adapters for High-Performance Plumbing Complete...

-

Engine Accessories - Performance Parts & Upgrades

Premium Engine Accessories - Performance Parts for Custom Builds & Motorsport Upgrade...

-

Fabrication Parts - Exhaust, Mandrel Bends & Weld Fittings

Premium Fabrication Parts - Custom Exhaust, Intake & Chassis ComponentsComplete your custom...

-

🚨 On Sale & Clearance stock 🚨

Current Package deals at SS Racetech Rods & Customs🔥click here! Shop SS...

-

SS Racetech New Arrivals Featuring Holley Carburetor Parts

Explore the newest arrivals at SS Racetech featuring Holley small parts...

-

ARP Fasteners - Head Studs, Main Studs & Rod Bolts

ARP Fasteners - Premium Head Studs, Main Studs & Engine Bolts Build...

-

Fuel Systems - Fuel Pumps, Regulators & AN Fittings

📋 Fuel System Plumbing Guide → Download our complete fuel system plumbing...

-

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps Upgrade...

-

Stainless Steel & Aluminium Bends and Tube

Premium Mandrel Bends & Tube for Custom Exhaust FabricationProfessional-grade stainless steel and...

-

Racing Seats

Shop Proforce Safety racing seats at SS Racetech Rods & Customs. Experience...

-

Safety Equipment - Quick Release Latches & Bonnet Pins

Safety Equipment - Quick Release Latches, Bonnet Pins & Racing Safety Ensure...

-

Suspension - Uniball Bearings, Rod Ends & Bushings

Premium Suspension Components - Uniball Bearings, Rod Ends & Bushings Upgrade your...

-

Rod Ends & Uniballs - FK Heim Joints

Premium Rod Ends, Uniballs & Heim Joints for Steering & Suspension High-performance...

-

Carburetors & Accessories - Spacers, Studs & Fuel Line Kits

Carburetors & Accessories - Spacers, Mounting Hardware & Fuel Lines Optimize your...

-

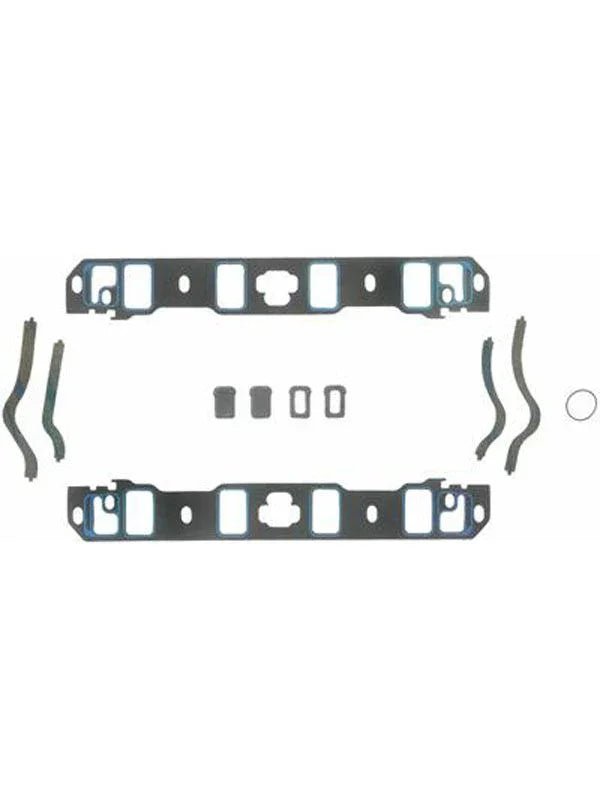

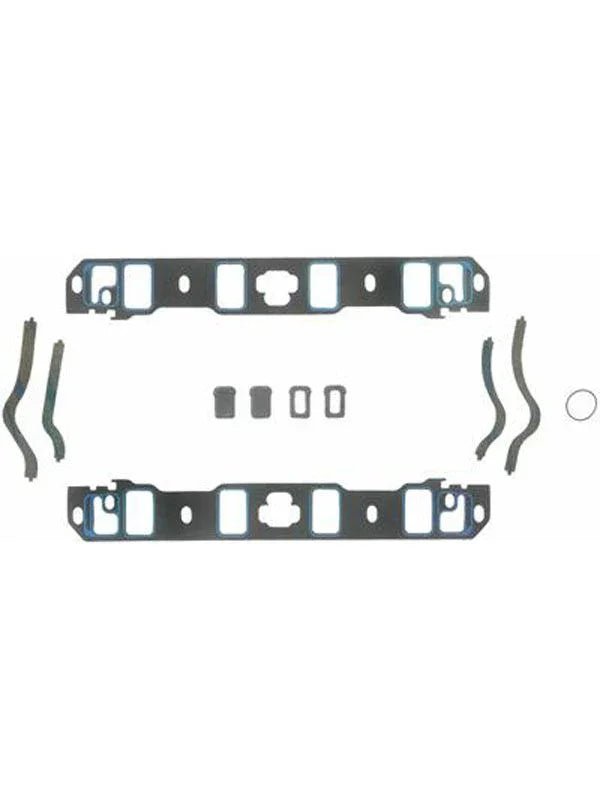

Gaskets - Intake, Exhaust & Engine Gasket Sets

Premium Engine Gaskets - Intake, Exhaust & Complete Gasket Sets Ensure leak-free...

-

Forced Induction

Explore the Forced Induction collection at SS Racetech Rods & Customs. Find...

-

Proflow Intake Manifolds - LS Holden Ford

High-Performance Proflow Intake Manifolds for LS, Holden & Ford EnginesUnlock peak engine...

-

Fuel Injection, Throttle Body's & Fuel Rails

Fuel Injection, Throttle Bodies & Fuel Rails – Precise Fuel Delivery for...

-

Cooling Systems - Oil Coolers, Transmission Coolers & Water Pumps

High-Performance Cooling Systems - Oil Coolers, Transmission Coolers & Heat Management Keep...

-

Drivetrain Components - Transmission & Driveline Parts

High-Performance Drivetrain, Transmission & Driveline Components Premium drivetrain parts for reliable power...

-

Race Suits / Apparel - Order in available!

Order in available! (We want to supply you with the newest dates...

-

Shocks & Springs

Fox bypass kit, Shaft, Bottom eyelet, King shocks rebuild kit, Fox mounting...

-

Silicone Hose, Bends and Reducers

Premium Silicone Hoses, Bends, Reducers & Brake Duct Hose SS Racetech stocks...

-

Steering & Shifters - Steering Columns & U-Joints

Steering & Shifters - Precision Control Components for Custom Builds Upgrade your...

-

Bearings & Seals

This collection offers Timken bearings, set 38, and oil seals. Find tapered...

-

Lubricants & Chemicals

Shop top-quality multi-purpose lubricant for cars and other high-performance automotive chemicals. Keep...

-

Electrical Components - Ignition, Alternators & Wiring

High-Performance Electrical Components - Ignition Systems, Alternators & Wiring Upgrade your vehicle's...

-

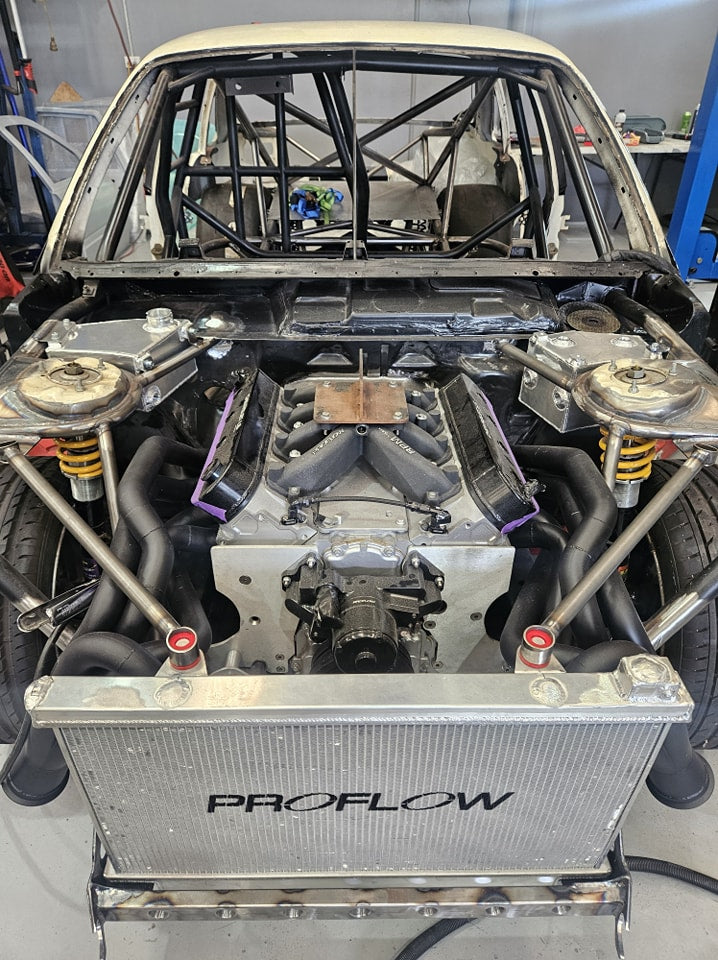

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds...

-

Custom Engines - Engine Rebuilds & Performance Builds

Custom Engine Builds - Rebuilds, Performance Upgrades & Complete Engines Unlock your...

-

Metric & Imperial Fasteners

SS Racetech Rods & Customs is your trusted source for...

-

Tyres & Wheels

Performance Tyres & Wheels for Race Cars & Street Machines High-performance tyres...

-

Drives & Pulleys - Performance Pulleys & Belt Tensioners

Drives & Pulleys - Performance Pulleys & Belt Tensioners Optimize your engine's...