Collection: Steel for Car Builders - Sheet, Tube & Fabrication Steel

Premium Steel for Car Builders - Sheet Metal, Tube & Fabrication Materials

Build with confidence using our comprehensive range of automotive-grade steel for custom car fabrication, chassis work, and performance builds. From cold-rolled sheet metal and hot-rolled plate to round tube, square tube, and precision-cut steel components, we stock everything Australian car builders, fabricators, and restorers need for professional results.

Sheet Metal & Plate Steel

- Cold-Rolled Sheet Steel: Smooth-finish sheet metal in various thicknesses (18ga, 16ga, 14ga, 12ga) for body panels, floor pans, and precision fabrication work

- Hot-Rolled Sheet Steel: Mill-finish plate steel for chassis components, mounting brackets, and structural fabrication where surface finish is less critical

- Galvanized Sheet Metal: Zinc-coated steel sheet for corrosion resistance in floor pans, inner panels, and rust repair applications

- Pre-Cut Sheet Sizes: Standard sizes and custom-cut sheets to minimize waste and simplify fabrication projects

Steel Tube & Round Bar

- Round Tube (CHS): Circular hollow section tube for roll cages, chassis bracing, suspension links, and custom fabrication in various diameters and wall thicknesses

- Square & Rectangular Tube (RHS/SHS): Structural hollow sections for chassis rails, subframes, mounting brackets, and fabrication jigs

- Solid Round Bar: Mild steel round bar for axles, pins, spacers, and machined components in common diameters

Common Car Building Applications

- Custom chassis fabrication and frame rails

- Roll cage and safety equipment construction

- Body panel repair and replacement

- Floor pan and firewall fabrication

- Suspension link and control arm fabrication

- Engine and transmission mounting brackets

- Fuel tank and battery box construction

- Custom exhaust hangers and mounting tabs

- Fabrication jigs and assembly fixtures

Related Fabrication Components

Complete your steel fabrication project with our range of complementary components:

- Weld-On Tabs: Laser-cut steel tabs for mounting and fabrication work

- Round Weld Bungs: Steel weld bungs for sensor and fitting installations

- 989 Series Weld Bungs: Universal weld-in fittings for fluid systems

- All Fabrication Parts: Complete range of exhaust, intake, and chassis fabrication components

- Stainless Steel Tube: Corrosion-resistant tubing for exhaust and exposed applications

-

Aluminium flat bar T5 MF 160 x 10.0 X 350 (GS018) 6060

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $52.00 AUDRegular price -

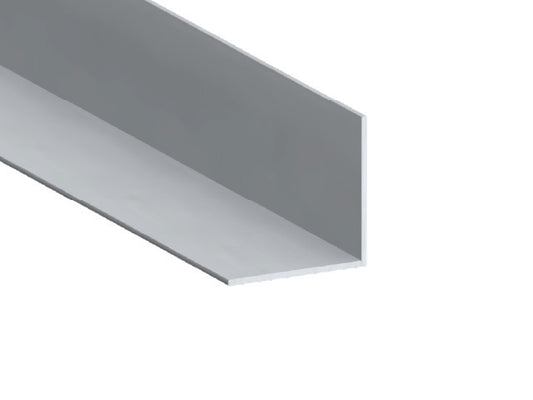

Angle Aluminium 80 X 80 X 6mm - Mill Finish 1 meter length

Vendor:SS Racetech Rods & CustomsRegular price $39.00 AUDRegular price -

Bright round bar 25.40 x 250mm

Vendor:SS Racetech Rods & CustomsRegular price $16.00 AUDRegular price -

Bright round bar 25.40 x 500mm

Vendor:SS Racetech Rods & CustomsRegular price $32.00 AUDRegular price -

Cold rolled sheet 0.95MM 600mm x 1200mm

Vendor:SS Racetech Rods & CustomsRegular price $42.40 AUDRegular price -

Cold rolled sheet 1.15MM 600mm x 1200mm

Vendor:SS Racetech Rods & CustomsRegular price $50.50 AUDRegular price -

Hot rolled sheet 1.60MM HA1 600 x 1200

Vendor:SS Racetech Rods & CustomsRegular price $94.80 AUDRegular price -

Hot rolled sheet 2.0MM HA1 600 x 1200

Vendor:SS Racetech Rods & CustomsRegular price $121.60 AUDRegular price -

Steel round bar 10mm x 1 meter length

Vendor:SS Racetech Rods & CustomsRegular price $3.50 AUDRegular price -

Steel round bar 6.3mm x 1 metre length

Vendor:SS Racetech Rods & CustomsRegular price $1.75 AUDRegular price -

Currently Unavailable

Currently UnavailableSteel round bar 8mm x 1 meter length

Vendor:SS Racetech Rods & CustomsRegular price $2.50 AUDRegular price

Shop by Engine

View all-

Air Filters - High-Flow Performance & Reusable Filters

High-Performance Air Filters - Washable, Reusable & High-Flow Maximize engine performance and...

-

Alternators & Accessories - High-Output Alternators & Brackets

Alternators & Accessories - High-Output Alternators & Mounting Brackets Upgrade your vehicle's...

-

Speedflow Hose - Braided Stainless Hose for Fuel, Oil & Brake

Premium Speedflow Braided Hose - Fuel, Oil, Coolant & Brake Lines Complete...

-

Speedflow Fittings

Premium Speedflow AN Fittings, Hose Ends & Adapters for High-Performance Plumbing Complete...

-

Engine Accessories - Performance Parts & Upgrades

Premium Engine Accessories - Performance Parts for Custom Builds & Motorsport Upgrade...

-

Fabrication Parts - Exhaust, Mandrel Bends & Weld Fittings

Premium Fabrication Parts - Custom Exhaust, Intake & Chassis Components Complete your...

-

ARP Fasteners - Head Studs, Main Studs & Rod Bolts

ARP Fasteners - Premium Head Studs, Main Studs & Engine Bolts Build...

-

Fuel Systems - Fuel Pumps, Regulators & AN Fittings

📋 Fuel System Plumbing Guide → Download our complete fuel system plumbing...

-

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps Upgrade...

-

Stainless Steel & Aluminium Bends and Tube

Premium Mandrel Bends & Tube for Custom Exhaust Fabrication Professional-grade stainless steel...

-

Racing Seats

Shop Proforce Safety racing seats at SS Racetech Rods & Customs. Experience...

-

Safety Equipment - Quick Release Latches & Bonnet Pins

Safety Equipment - Quick Release Latches, Bonnet Pins & Racing Safety Ensure...

-

Suspension - Uniball Bearings, Rod Ends & Bushings

Premium Suspension Components - Uniball Bearings, Rod Ends & Bushings Upgrade your...

-

Rod Ends & Uniballs - FK Heim Joints

Premium Rod Ends, Uniballs & Heim Joints for Steering & Suspension High-performance...

-

Carburetors & Accessories - Spacers, Studs & Fuel Line Kits

Carburetors & Accessories - Spacers, Mounting Hardware & Fuel Lines Optimize your...

-

Gaskets - Intake, Exhaust & Engine Gasket Sets

Engine Gaskets - Intake, Exhaust & Complete Gasket Sets High-quality gaskets for...

-

Forced Induction

Forced Induction - Turbocharger Parts & AccessoriesPremium forced induction components for turbocharged...

-

Proflow Intake Manifolds - LS Holden Ford

High-Performance Proflow Intake Manifolds for LS, Holden & Ford EnginesUnlock peak engine...

-

Fuel Injection, Throttle Body's & Fuel Rails

Fuel Injection, Throttle Bodies & Fuel Rails – Precise Fuel Delivery for...

-

Cooling Systems - Oil Coolers, Transmission Coolers & Water Pumps

High-Performance Cooling Systems - Oil Coolers, Transmission Coolers & Heat Management Keep...

-

Drivetrain Components - Transmission & Driveline Parts

High-Performance Drivetrain, Transmission & Driveline ComponentsPremium drivetrain parts for reliable power transfer...

-

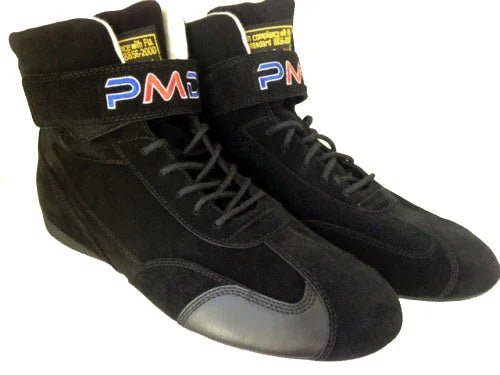

Race Suits / Apparel - Order in available!

Order in available! (We want to supply you with the newest dates...

-

Shocks & Springs

Fox bypass kit, Shaft, Bottom eyelet, King shocks rebuild kit, Fox mounting...

-

Silicone Hose, Bends and Reducers

Premium Silicone Hoses, Bends, Reducers & Brake Duct Hose SS Racetech stocks...

-

Steering & Shifters - Steering Columns & U-Joints

Steering & Shifters - Precision Control Components for Custom Builds Upgrade your...

-

Bearings & Seals

This collection offers Timken bearings, set 38, and oil seals. Find tapered...

-

Lubricants & Chemicals

Shop top-quality multi-purpose lubricant for cars and other high-performance automotive chemicals. Keep...

-

Electrical Components - Ignition, Alternators & Wiring

High-Performance Electrical Components - Ignition Systems, Alternators & Wiring Upgrade your vehicle's...

-

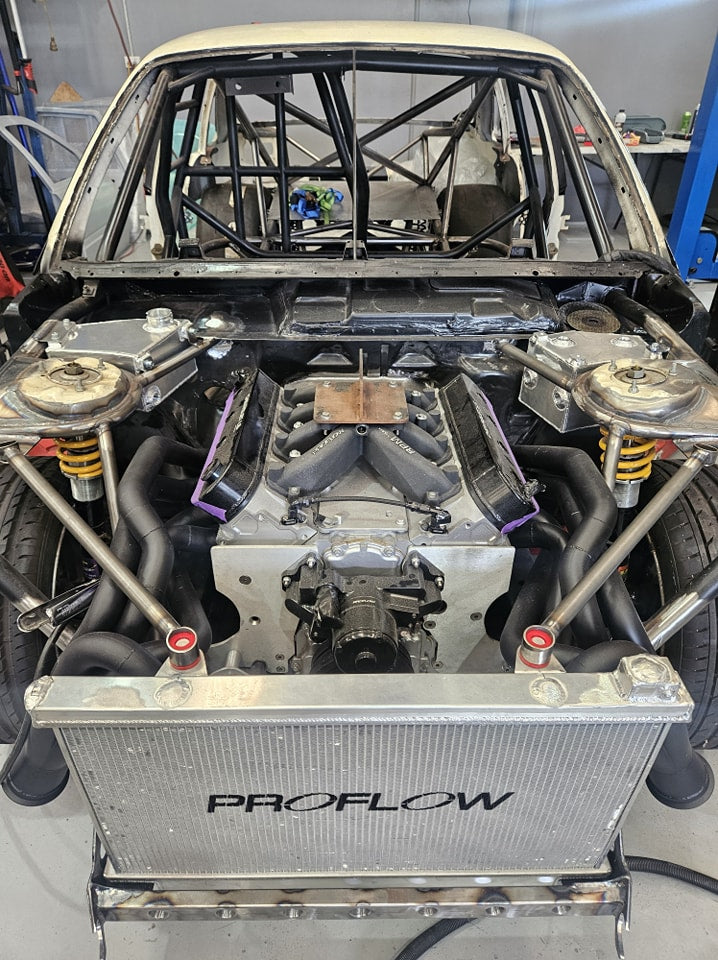

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds...

-

Custom Engines - Engine Rebuilds & Performance Builds

Custom Engine Builds - Rebuilds, Performance Upgrades & Complete Engines Unlock your...

-

Metric & Imperial Fasteners

SS Racetech Rods & Customs is your trusted source for...

-

Tyres & Wheels

Performance Tyres & Wheels for Race Cars & Street Machines High-performance tyres...

-

Drives & Pulleys - Performance Pulleys & Belt Tensioners

Drives & Pulleys - Performance Pulleys & Belt Tensioners Optimize your engine's...