Collection: ARP Main Stud kits

ARP Main Stud Kits - Bulletproof Your Engine's Bottom End

Prevent catastrophic main bearing cap failure with ARP's precision-engineered main stud kits. Designed for high-horsepower engines, forced induction, and racing applications, these kits eliminate main cap walk, prevent fretting, and provide superior clamping force compared to factory bolts that can stretch and loosen under extreme loads.

Why Main Studs Are Critical for Performance Engines

Factory main cap bolts are adequate for stock power levels but become the weak link in high-performance builds. Under high cylinder pressures from boost, nitrous, or high compression, main caps can shift (walk), causing bearing damage, oil pressure loss, and catastrophic engine failure. ARP main studs provide 2-3 times the clamping force of stock bolts, keeping main caps precisely located and preventing the fretting and movement that destroys bearings and blocks.

ARP Main Stud Kit Features:

- 200,000 PSI Tensile Strength: Heat-treated 8740 chromoly steel provides maximum strength and fatigue resistance

- Precision Thread Rolling: Threads rolled after heat treatment for superior strength compared to cut threads

- Eliminates Main Cap Walk: Superior clamping force prevents cap movement under extreme cylinder pressures

- Protects Block Threads: Studs install once and stay in place, eliminating repeated threading that damages aluminium blocks

- 12-Point Nuts: Precision 12-point nuts allow accurate torque application and prevent rounding

- Complete Kits: Includes studs, hardened washers, and nuts for complete installation

- Black Oxide Finish: Corrosion-resistant coating for long-lasting durability

Common Applications:

- Turbocharged and supercharged engines (boost applications)

- High-compression naturally aspirated race engines

- Nitrous oxide equipped engines

- LS engine builds (LS1, LS2, LS3, LS6, LS7, LSX)

- Small block and big block Chevy performance builds

- Ford Windsor, Cleveland, and Modular engine builds

- Any engine rebuild exceeding 500+ horsepower

- Drag racing, road racing, and endurance racing applications

Installation Requirements:

Professional Installation Recommended: Main stud installation requires complete engine disassembly and precise torque procedures. This is typically done during engine building or major rebuilds.

ARP Ultra-Torque Required: Always use ARP Ultra-Torque assembly lubricant and follow ARP's specific torque specifications for your engine. Torque in multiple stages using a crisscross pattern.

Main Cap Alignment: Some engines may require main cap alignment honing after stud installation to ensure proper bearing clearances. Consult your engine builder.

Block Preparation: Ensure block threads are clean and undamaged. Chase threads with a tap if necessary before stud installation.

Why Choose ARP?

ARP (Automotive Racing Products) is the world leader in fastener technology, trusted by professional race teams, engine builders, and performance enthusiasts worldwide. Every ARP main stud kit is manufactured in the USA to aerospace standards and individually tested for quality assurance.

Australian Stock: Fast shipping from Perth, Western Australia. ARP main stud kits available for most popular performance engines.

-

Currently Unavailable

Currently UnavailableARP 134-5401 Main Stud Kit Small Block Chevy Large Journal 2 Bolt 6 Point Hex

Vendor:SS Racetech Rods & CustomsRegular price $138.50 AUDRegular price -

ARP 234-4317 ARP Cylinder Head Stud, Pro-Series, 12-point Head, For Chevrolet, LS Series, Gen III/IV 2004 & Later, Same Length Studs, Kit

Vendor:SS Racetech Rods & CustomsRegular price $693.80 AUDRegular price -

ARP Cylinder Head Studs Pro Series Hex Head Chevrolet LS Gen III 2003 & Earlier 4 Short 16 Long 190,000 PSI Kit ARP-234-4110

Vendor:SS Racetech Rods & CustomsRegular price $717.80 AUDRegular price -

ARP Main Studs 2-Bolt Main 8740 Chrome Moly Ford 289 302W Windsor 190,000 PSI Kit ARP-154-5401

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $137.15 AUDRegular price -

ARP Main Studs 2-Bolt Main 8740 Chrome Moly Ford 351W Windsor Dual/Rear Sump Oil Pan 190,000 PSI Kit ARP-154-5409

Vendor:SS Racetech Rods & CustomsNo reviewsRegular price $180.15 AUDRegular price -

ARP-205-4602 ARP Cylinder Head Stud, Pro-Series, 12-point Head U/C Studs, For Holden, 308 cid w/ 12, Kit

Vendor:SS Racetech Rods & CustomsRegular price $368.50 AUDRegular price -

Currently Unavailable

Currently UnavailableARP-205-5401 ARP Main Studs, 2-Bolt Main, For Holden 308 V8, Kit

Vendor:SS Racetech Rods & CustomsRegular price $123.00 AUDRegular price

-

Air Filters - High-Flow Performance & Reusable Filters

High-Performance Air Filters - Washable, Reusable & High-Flow Maximize engine performance and...

-

Alternators & Accessories - High-Output Alternators & Brackets

Alternators & Accessories - High-Output Alternators & Mounting Brackets Upgrade your vehicle's...

-

Speedflow Hose - Braided Stainless Hose for Fuel, Oil & Brake

Premium Speedflow Braided Hose - Fuel, Oil, Coolant & Brake Lines Complete...

-

Speedflow Fittings

Premium Speedflow AN Fittings, Hose Ends & Adapters for High-Performance Plumbing Complete...

-

Engine Accessories - Performance Parts & Upgrades

Premium Engine Accessories - Performance Parts for Custom Builds & Motorsport Upgrade...

-

Fabrication Parts - Exhaust, Mandrel Bends & Weld Fittings

Premium Fabrication Parts - Custom Exhaust, Intake & Chassis Components Complete your...

-

🚨 On Sale & Clearance stock 🚨

Current Package deals at SS Racetech Rods & Customs🔥click here! Shop SS...

-

SS Racetech New Arrivals Featuring Holley Carburetor Parts

Explore the newest arrivals at SS Racetech featuring Holley small parts...

-

ARP Fasteners - Head Studs, Main Studs & Rod Bolts

ARP Fasteners - Premium Head Studs, Main Studs & Engine Bolts Build...

-

Fuel Systems - Fuel Pumps, Regulators & AN Fittings

📋 Fuel System Plumbing Guide → Download our complete fuel system plumbing...

-

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps

Brakes & Pedals - Brake Lines, AN Fittings & Hardline Clamps Upgrade...

-

Stainless Steel & Aluminium Bends and Tube

Premium Mandrel Bends & Tube for Custom Exhaust Fabrication Professional-grade stainless steel...

-

Racing Seats

Shop Proforce Safety racing seats at SS Racetech Rods & Customs. Experience...

-

Safety Equipment - Quick Release Latches & Bonnet Pins

Safety Equipment - Quick Release Latches, Bonnet Pins & Racing Safety Ensure...

-

Suspension - Uniball Bearings, Rod Ends & Bushings

Premium Suspension Components - Uniball Bearings, Rod Ends & Bushings Upgrade your...

-

Rod Ends & Uniballs - FK Heim Joints

Premium Rod Ends, Uniballs & Heim Joints for Steering & Suspension High-performance...

-

Carburetors & Accessories - Spacers, Studs & Fuel Line Kits

Carburetors & Accessories - Spacers, Mounting Hardware & Fuel Lines Optimize your...

-

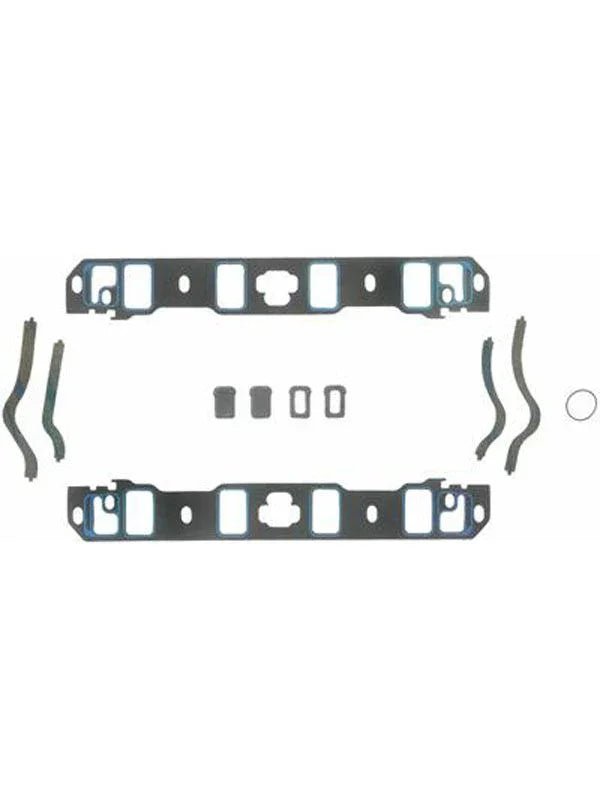

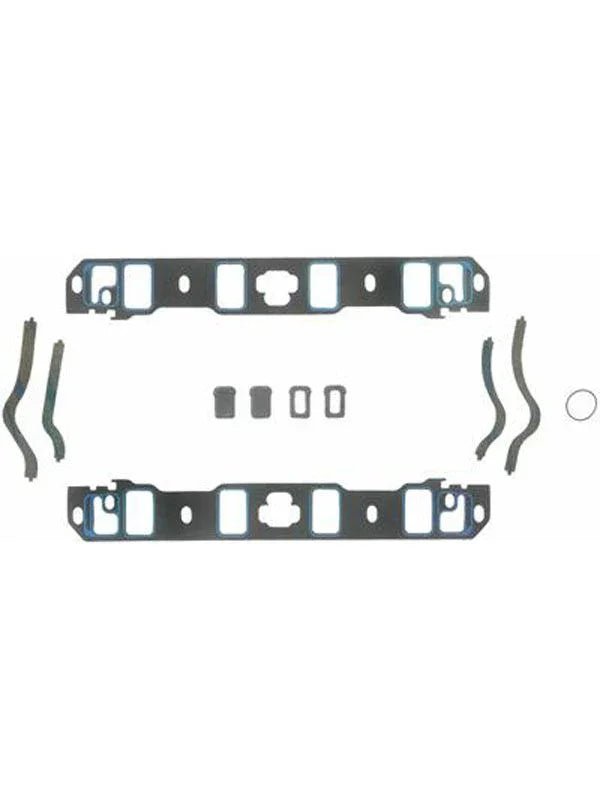

Gaskets - Intake, Exhaust & Engine Gasket Sets

Premium Engine Gaskets - Intake, Exhaust & Complete Gasket Sets Ensure leak-free...

-

Forced Induction

Explore the Forced Induction collection at SS Racetech Rods & Customs. Find...

-

Proflow Intake Manifolds - LS Holden Ford

High-Performance Proflow Intake Manifolds for LS, Holden & Ford EnginesUnlock peak engine...

-

Fuel Injection, Throttle Body's & Fuel Rails

Fuel Injection, Throttle Bodies & Fuel Rails – Precise Fuel Delivery for...

-

Cooling Systems - Oil Coolers, Transmission Coolers & Water Pumps

High-Performance Cooling Systems - Oil Coolers, Transmission Coolers & Heat Management Keep...

-

Drivetrain Components - Transmission & Driveline Parts

High-Performance Drivetrain, Transmission & Driveline Components Premium drivetrain parts for reliable power...

-

Race Suits / Apparel - Order in available!

Order in available! (We want to supply you with the newest dates...

-

Shocks & Springs

Fox bypass kit, Shaft, Bottom eyelet, King shocks rebuild kit, Fox mounting...

-

Silicone Hose, Bends and Reducers

Premium Silicone Hoses, Bends, Reducers & Brake Duct Hose SS Racetech stocks...

-

Steering & Shifters - Steering Columns & U-Joints

Steering & Shifters - Precision Control Components for Custom Builds Upgrade your...

-

Bearings & Seals

This collection offers Timken bearings, set 38, and oil seals. Find tapered...

-

Lubricants & Chemicals

Shop top-quality multi-purpose lubricant for cars and other high-performance automotive chemicals. Keep...

-

Electrical Components - Ignition, Alternators & Wiring

High-Performance Electrical Components - Ignition Systems, Alternators & Wiring Upgrade your vehicle's...

-

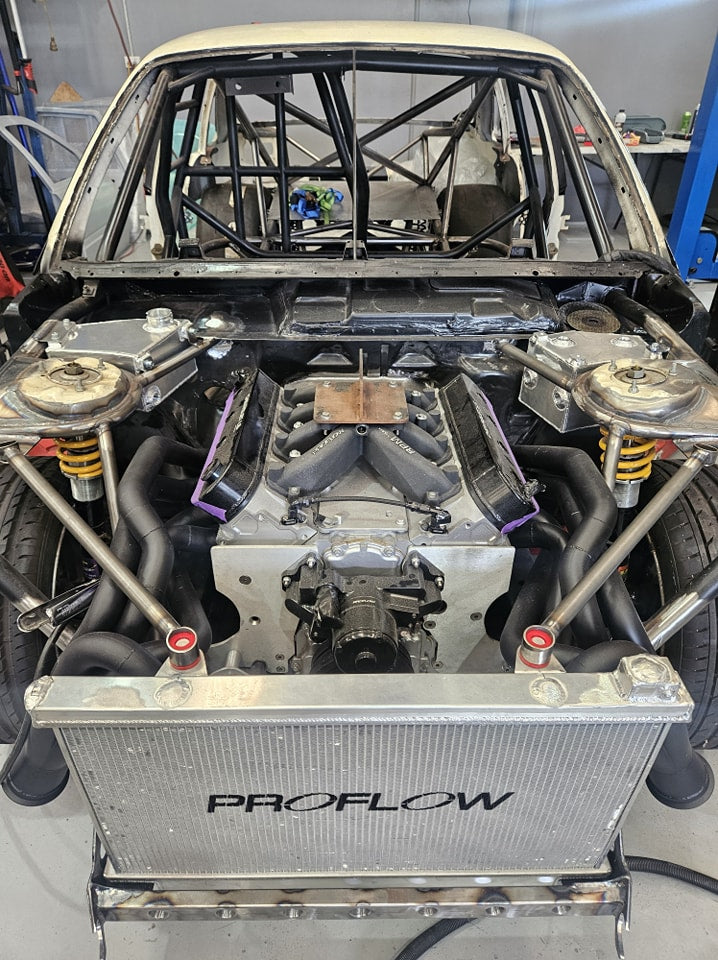

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds

SS Racetech Rods & Customs - Custom Hot Rods & Performance Builds...

-

Custom Engines - Engine Rebuilds & Performance Builds

Custom Engine Builds - Rebuilds, Performance Upgrades & Complete Engines Unlock your...

-

Metric & Imperial Fasteners

SS Racetech Rods & Customs is your trusted source for...

-

Tyres & Wheels

Performance Tyres & Wheels for Race Cars & Street Machines High-performance tyres...

-

Drives & Pulleys - Performance Pulleys & Belt Tensioners

Drives & Pulleys - Performance Pulleys & Belt Tensioners Optimize your engine's...